Essential Checklist for Choosing the Right Wood CNC Machine for Your Business Needs

In the rapidly evolving landscape of woodworking and manufacturing, the demand for advanced machinery has surged, particularly for wood CNC machines. According to a recent report by Markets and Markets, the global CNC machine market is projected to grow to over $100 billion by 2026, with wood CNC machines playing a pivotal role in this expansion due to their precision and versatility. Businesses are increasingly relying on these machines to streamline production, enhance customization, and improve efficiency in their woodworking processes. However, with a myriad of options available, choosing the right wood CNC machine can be a daunting task. This essential checklist aims to guide decision-makers through the critical aspects to consider, enabling them to select a machine that aligns with their specific business needs and operational goals.

Key Factors to Consider When Selecting a Wood CNC Machine for Your Business

When selecting a wood CNC machine for your business, it’s essential to consider several key factors that can significantly impact your operational efficiency and production quality. First, assess the machine's size and capabilities in relation to your specific projects. A larger machine may be necessary for intricate designs or mass production, while a smaller model could suffice for more straightforward tasks. Understanding your project requirements will ensure you choose the right machine that fits well within your workspace without compromising on functionality.

When selecting a wood CNC machine for your business, it’s essential to consider several key factors that can significantly impact your operational efficiency and production quality. First, assess the machine's size and capabilities in relation to your specific projects. A larger machine may be necessary for intricate designs or mass production, while a smaller model could suffice for more straightforward tasks. Understanding your project requirements will ensure you choose the right machine that fits well within your workspace without compromising on functionality.

Another important factor is the software compatibility of the CNC machine. Many modern wood CNC machines come with advanced software solutions that facilitate design and production processes. Make sure the machine you select is compatible with the design tools you plan to use. This will enhance your workflow and reduce any potential learning curve for your team. Additionally, consider the machine's ease of use and maintenance; a user-friendly interface and reliable support can significantly improve your business operation and minimize downtime. By carefully evaluating these key factors, you can select a wood CNC machine that meets your business needs effectively.

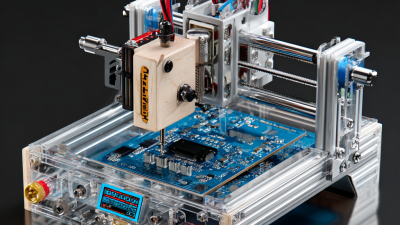

Understanding Different Types of Wood CNC Machines and Their Applications

When choosing the right wood CNC machine for your business needs, it’s crucial to understand the various types available and their specific applications. There are primarily three types of wood CNC machines: routers, laser cutters, and milling machines. According to a recent report by Grand View Research, the global CNC woodworking machine market is expected to grow at a CAGR of 5.2% from 2021 to 2028, indicating a rising demand for these advanced tools in the woodworking industry.

CNC routers are versatile machines ideal for intricate designs and patterns, making them suitable for furniture manufacturing and decorative elements. On the other hand, laser cutters provide precision and are excellent for engraving and cutting detailed shapes, which is especially beneficial for crafting personalized items or signage. Milling machines, known for their durability and heavy-duty capabilities, are perfect for large-scale production and machining solid wood, providing efficiency and high-quality results in production environments.

Understanding the strengths and limitations of each type can significantly impact your operational efficiency and product quality. Investing in the right wood CNC machine tailored to your specific applications can enhance your production capabilities and meet market demands effectively. By aligning your choice with current industry trends and technologies, you position your business to leverage the full benefits of CNC machining in the woodworking sector.

Essential Checklist for Choosing the Right Wood CNC Machine for Your Business Needs

| Machine Type | Applications | Max Cutting Area | Spindle Power | Price Range |

|---|---|---|---|---|

| Entry-Level CNC Router | Hobby Projects, Small Signage | 24" x 36" | 1.5 HP | $1,500 - $3,000 |

| Mid-Range CNC Router | Furniture Making, Cabinetry | 48" x 96" | 3 HP | $6,000 - $12,000 |

| Industrial CNC Router | Mass Production, Large Scale Projects | 60" x 120" | 10 HP | $20,000 - $100,000 |

| CNC Laser Cutter | Intricate Designs, Fine Detailing | 36" x 24" | 40W - 120W | $2,000 - $15,000 |

Evaluating Efficiency: Speed, Precision, and Operating Costs in Wood CNC Machines

When choosing a wood CNC machine, evaluating efficiency is paramount. Three key factors come into play: speed, precision, and operating costs. Speed determines how quickly a machine can complete a task, which directly impacts productivity levels in your business. A faster machine can boost output, but it's essential to balance speed with precision. A tool that rushes through projects may compromise the quality of the cut or engraving, leading to higher rejection rates and wasted material.

Precision, on the other hand, is critical for achieving the desired results in woodworking. A machine with high precision ensures that intricate designs and detailed patterns are rendered accurately. You'll want to consider the machine's capabilities regarding tolerances and the type of projects you’ll be undertaking. Lastly, operational costs cannot be overlooked. While a high-speed, high-precision machine may seem appealing, it’s important to assess maintenance costs, power consumption, and the price of replacement parts. The right balance of these aspects will ultimately influence the long-term profitability and sustainability of your woodworking business.

Assessing Customer Support and Warranty Options for CNC Equipment

When investing in a wood CNC machine, evaluating customer support and warranty options is paramount. According to a survey by the International Woodworking Fair, nearly 70% of companies reported that sufficient customer support directly influenced their purchasing decisions. Robust support not only ensures that you can maximize the use of your CNC equipment but also decreases downtime significantly. Machines can be complex, and having access to knowledgeable support personnel can help troubleshoot issues quickly, ensuring your production line remains efficient.

Tip: Always inquire about the availability of customer support after hours or during holidays. A manufacturer offering 24/7 support can be a lifesaver when you encounter unexpected operational challenges.

In addition to customer support, assessing warranty options is crucial. A study by the Association of Woodworking and Furniture Suppliers indicated that a comprehensive warranty can add up to 20% to the perceived value of industrial equipment. This means that when it comes time to service or replace parts, having a solid warranty agreement can protect your investment, allowing you to manage costs effectively.

Tip: Don't just look for the length of the warranty; evaluate the extent of coverage. Understanding what is included can save you from future repair expenses.

Essential Checklist for Choosing the Right Wood CNC Machine for Your Business Needs

This bar chart illustrates key factors to consider when selecting a wood CNC machine, focusing on customer support and warranty options.

Analyzing Industry Trends: How Technological Advances Impact CNC Machine Selection

As the woodworking industry evolves, the selection of the right CNC machine is increasingly influenced by technological advancements and shifting market trends. With the global machine tool market projected to grow from $13.63 billion in 2025 to $22.946 billion by 2032, a compound annual growth rate (CAGR) of 8.1% signals significant demand for innovative solutions. Businesses looking to invest in wood CNC machines must consider these trends to stay competitive.

The rise of automated processes and smart technology integration in CNC machines has transformed manufacturing efficiency. Features such as real-time monitoring, enhanced precision, and adaptive machining not only improve productivity but also reduce operational costs. Additionally, the increasing market for electric motors and industrial sewing machines, expected to reach substantial market values by 2032, indicates a broader shift towards integrating advanced machinery into various sectors, including woodworking. By understanding these industry dynamics, businesses can make informed decisions about their CNC machine investments, ensuring they choose solutions that align with both current capabilities and future growth potential.

Related Posts

-

Discovering Quality Suppliers for the Best Mini CNC Machine in a Competitive Market

-

Global Sourcing Chinese Excellence: Why the Best CNC Lathe Machines Dominate World Markets

-

Finding Reliable Manufacturers for the Best Small CNC Mill Solutions

-

Discovering the Advantages of the Best Smart CNC Technology for Modern Manufacturing

-

Excellence in Manufacturing from China Bringing the Best Mini CNC Machines to the World

-

Discover Superior Manufacturing with the Best Desktop CNC Mill from Top Chinese Factories

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska