The Ultimate CNC Lathe Buying Guide: Key Factors for Global Procurement Success

In the rapidly evolving landscape of manufacturing, the CNC lathe has emerged as a pivotal tool, streamlining production processes and enhancing precision across various industries. According to a report by MarketsandMarkets, the global CNC lathe market is projected to grow from USD 2.3 billion in 2020 to USD 3.1 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.5%. This surge underscores the importance of making informed procurement decisions when investing in CNC lathes.

As manufacturers seek to improve efficiency and reduce costs, understanding the key factors that influence CNC lathe selection is crucial. This ultimate buying guide will explore essential considerations such as machine capabilities, supplier reliability, and technological advancements, providing valuable insights for global procurement success in the world of CNC machining.

Understanding CNC Lathes: Types and Functions for Optimal Selection

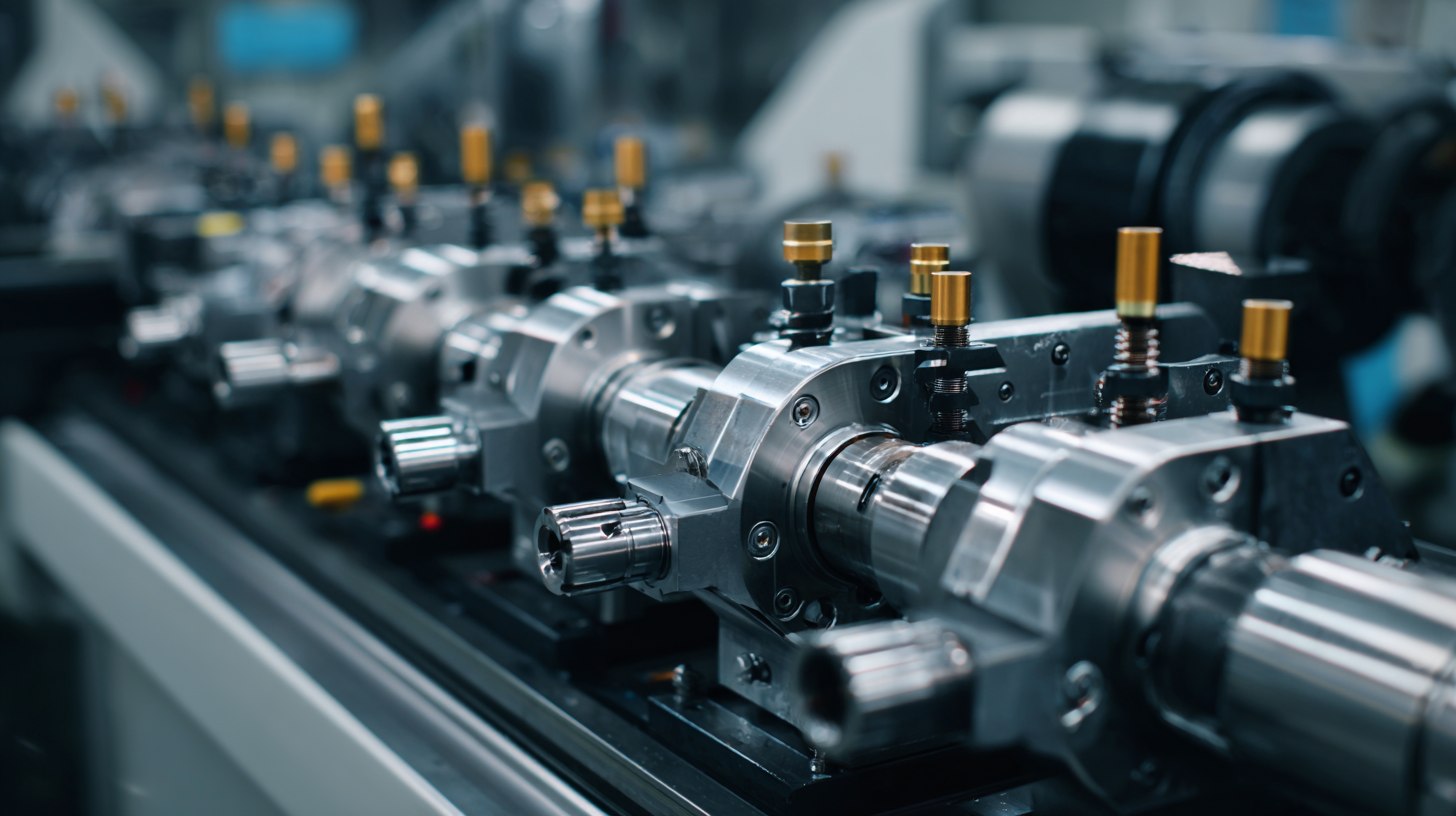

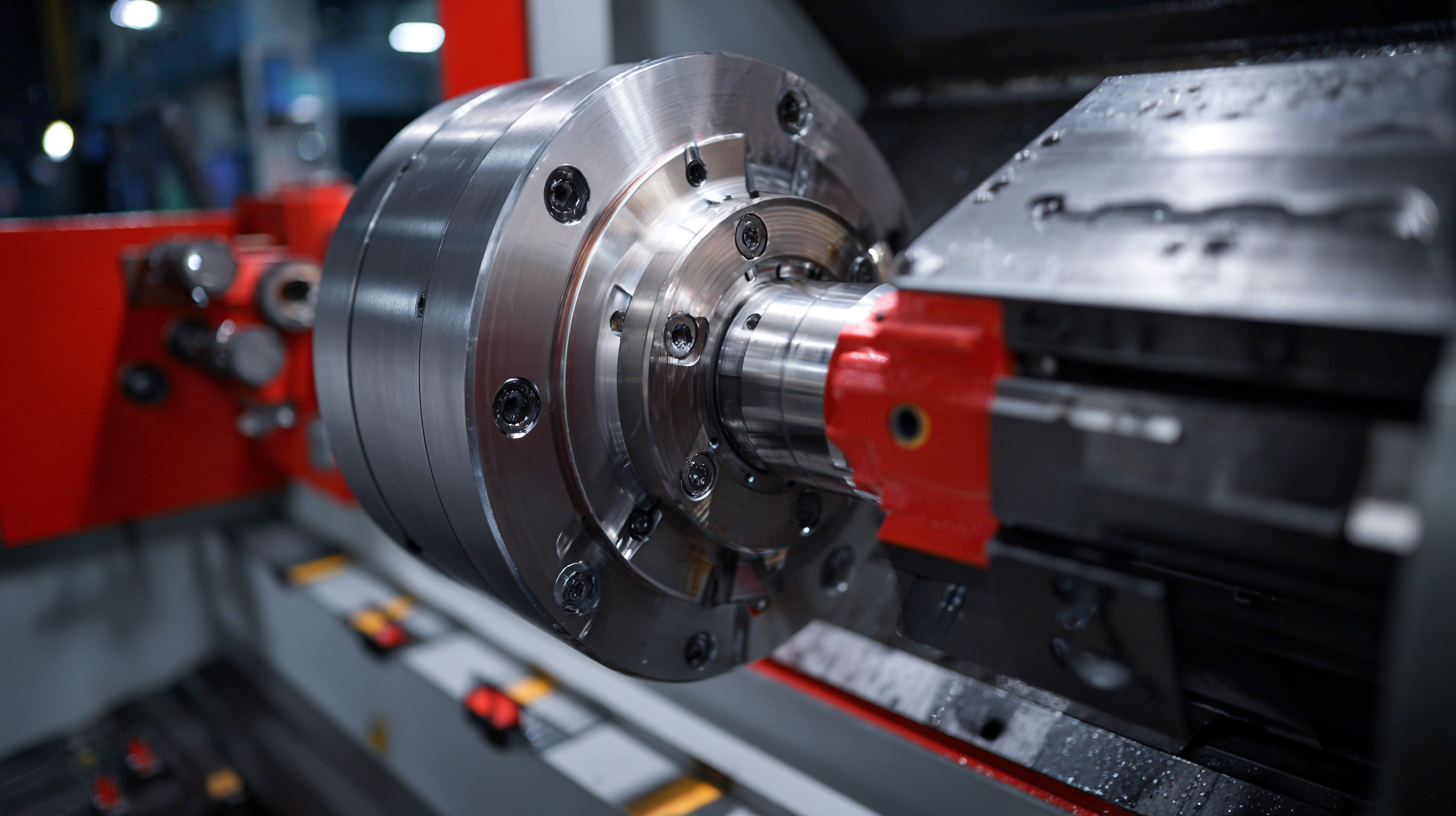

When considering the purchase of a CNC lathe, understanding the various types and their functions is essential for making an informed decision. CNC lathes primarily fall into three categories: horizontal lathes, vertical lathes, and multi-tasking machines. Horizontal lathes are the most common and are ideal for a wide range of machining tasks. They are designed to handle cylindrical workpieces and offer better accessibility for operators, making them suitable for small to medium-sized production runs.

Vertical lathes excel in machining larger and heavier workpieces, providing stability and precision. Their design allows for easy loading and unloading of materials, which can enhance productivity in large-scale operations. Multi-tasking CNC lathes combine multiple functions, such as turning, milling, and grinding, into one machine, making them versatile for complex jobs. Selecting the right type of CNC lathe based on the specific production requirements and the complexity of your projects can significantly impact efficiency and cost-effectiveness in your manufacturing processes.

The Ultimate CNC Lathe Buying Guide: Key Factors for Global Procurement Success

| Type of CNC Lathe | Function | Ideal Usage | Typical Features | Price Range (USD) |

|---|---|---|---|---|

| Vertical CNC Lathe | Turning of large, heavy workpieces | Heavy-duty machining | Rotary table, vertical spindle | $30,000 - $120,000 |

| Horizontal CNC Lathe | General purpose turning tasks | Precision components | Automatic tool change, programmable | $20,000 - $80,000 |

| CNC Swiss Lathe | High-speed precision machining | Small diameter precision parts | Sliding headstock, live tooling | $50,000 - $150,000 |

| Predictive CNC Lathe | Predictive maintenance and diagnostics | Automation in monitoring | Sensors, data analytics | $80,000 - $200,000 |

| Toolroom CNC Lathe | Tool making and repair | Educational and small batch production | Variably turret, manual controls | $10,000 - $40,000 |

Key Features to Consider When Choosing a CNC Lathe for Your Business

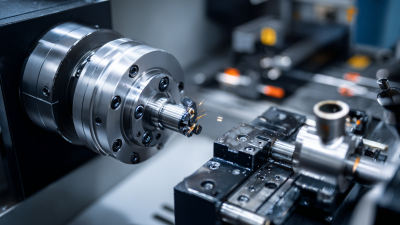

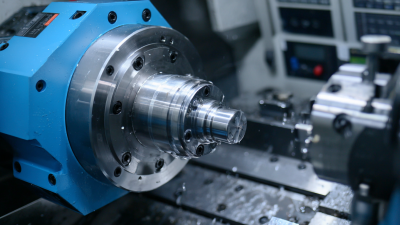

When selecting a CNC lathe for your business, several key features should be considered to ensure optimal performance and efficiency. First and foremost, the machine's size and capacity must align with your production requirements. A lathe that is too small may limit your capabilities, while one that is overly large can lead to increased operational costs. It's crucial to evaluate the diameter and length of the workpieces you'll typically be handling.

Additionally, the control system of the CNC lathe plays a significant role in its usability and versatility. Modern CNC lathes come equipped with advanced software that offers improved programming capabilities and user-friendly interfaces. Features like automated tool changers can significantly reduce downtime and enhance productivity.

Lastly, consider the machine's construction quality; a robust and well-engineered lathe can improve precision and extend the longevity of your investment, which is essential in a rapidly growing market projected to expand to $195.59 billion by 2032.

Evaluating CNC Lathe Manufacturers: What to Look for in Your Supplier

When evaluating CNC lathe manufacturers, several critical factors should guide your decision-making process. First and foremost, assess the manufacturer's reputation within the industry. Look for companies with a proven track record of quality and reliability. Customer reviews, testimonials, and case studies can provide valuable insights into the manufacturer’s performance and their commitment to meeting client needs. Additionally, ensure that the manufacturer is compliant with relevant quality standards and certifications, as this reflects their adherence to industry best practices.

Another vital aspect is the range of products offered. A diversified product line can indicate a manufacturer’s capability to meet various machining requirements and adapt to evolving technologies. It’s beneficial to choose a supplier who not only offers traditional CNC lathes but also includes options for automation and advanced features. Finally, consider the availability of comprehensive customer support and service. A manufacturer that prioritizes after-sales support can significantly enhance your procurement experience, ensuring that you receive timely assistance and maintenance, ultimately leading to a successful long-term partnership.

The Ultimate CNC Lathe Buying Guide: Key Factors for Global Procurement Success

This chart illustrates the key factors to consider when evaluating CNC lathe manufacturers, based on a survey of industry professionals. The factors include Precision, Cost, Support, Delivery Time, and Technology. Understanding these aspects is crucial for successful procurement.

Budgeting for Your CNC Lathe Purchase: Costs and Financing Options

When considering the purchase of a CNC lathe, budgeting is a critical factor that can significantly influence the success of your procurement. The overall cost of CNC lathes varies widely, with entry-level models often starting from around $5,000, while high-end machines can exceed $100,000. According to recent industry reports, companies typically allocate about 15-20% of their overall manufacturing budget to CNC equipment, emphasizing the importance of financial planning in this investment.

Financing options can further ease the burden of purchasing a CNC lathe. Many manufacturers and dealers offer leasing programs, which allow businesses to acquire the necessary equipment without the heavy upfront costs. Additionally, businesses can explore loans specifically designed for machinery purchases, which often have favorable terms and interest rates compared to general business loans. An industry survey revealed that approximately 40% of manufacturers are using financing options to fund their equipment purchases, which highlights the growing trend of leveraging financial solutions to optimize capital allocation.

Understanding these budgeting considerations and financing alternatives is essential for organizations aiming to enhance their manufacturing capabilities while maintaining financial stability. With careful planning and the right financial strategy, acquiring a CNC lathe can become a more attainable goal for businesses of all sizes.

Navigating Global Procurement: Best Practices for Importing CNC Lathes

When navigating the complexities of global procurement for CNC lathes, understanding the market landscape is crucial. The first step in this process involves conducting thorough research on potential suppliers. Look for manufacturers with a solid reputation, positive customer reviews, and proven experience in producing high-quality CNC machinery. It's also wise to consider suppliers who offer comprehensive service packages, including installation and after-sales support, as this can significantly enhance your overall experience.

Another important factor is to leverage technological advancements in procurement. Utilizing online platforms can streamline the process of comparing prices, specifications, and lead times from multiple suppliers. Moreover, engaging in direct communication with manufacturers can lead to better negotiation outcomes. Always request detailed quotations and clarify terms regarding warranty, delivery, and payment options. Building a solid relationship with reliable suppliers not only boosts your procurement success but also paves the way for future collaborations, ensuring you receive the best equipment tailored to your operational needs.

Related Posts

-

Setting the Gold Standard: Industry Production Guidelines for the Best CNC Lathes

-

Global Sourcing Chinese Excellence: Why the Best CNC Lathe Machines Dominate World Markets

-

Unlocking Precision: 7 Key Benefits of the Best CNC Machines for Your Business

-

The Future of Advanced CNC Machine Technologies in Global Manufacturing

-

Unlock Superior Manufacturing with the Best Smart CNC: A Premier Chinese Factory Solution

-

Unlocking Efficiency and Precision with Best CNC Manufacturing Solutions

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska