Exploring the Impact of CNC Metal Machining on Modern Manufacturing Efficiency and Precision

The advent of CNC metal machining has transformed the landscape of modern manufacturing, significantly enhancing both efficiency and precision. According to a report by Grand View Research, the global CNC machining market was valued at approximately $63.4 billion in 2021 and is projected to expand at a compound annual growth rate (CAGR) of 6.5% from 2022 to 2030. This evolution is largely attributed to the integration of advanced Computer Numerical Control (CNC) technology, which allows for the automation of complex machining processes and minimizes human error. As industries increasingly adopt CNC metal machining techniques, they benefit from improved production speeds and a dramatic reduction in material waste, thereby optimizing overall operational productivity. This article will explore how CNC metal machining not only elevates manufacturing standards but also aligns with the industry's ongoing efforts to adapt to technological advancements and market demands.

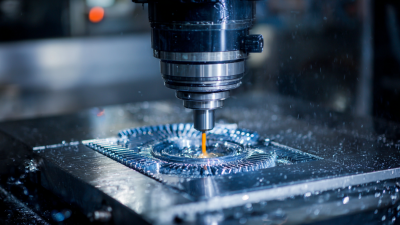

The Evolution of CNC Metal Machining in Modern Manufacturing Practices

The evolution of CNC metal machining has significantly transformed modern manufacturing practices, enhancing both efficiency and precision. As industries shift towards automation and advanced manufacturing techniques, CNC (Computer Numerical Control) machining stands at the forefront, allowing for intricate designs and higher productivity rates. According to recent industry reports, the global CNC milling machine market is projected to reach a value of $16,626 million by 2025, with an anticipated growth to $26,699.9 million by 2033, reflecting a compound annual growth rate (CAGR) of 6.1%. This continuous growth underscores the increasing reliance on CNC technology to meet the demands of modern production.

As manufacturers embrace CNC technologies, the benefits become evident. CNC metal machining offers unparalleled precision in fabricating components, enabling companies to maintain rigorous quality standards while reducing waste. The ability to automate production processes not only enhances throughput but also minimizes human error, leading to consistent quality and reduced lead times. With advancements in software and machine capabilities, manufacturers are now able to leverage CNC machines for more complex operations, paving the way for innovative product development and enhanced competitive advantage in various markets.

Quantifying Efficiency Gains: CNC Machining vs. Traditional Methods in Production Rates

The advancement of CNC metal machining has significantly outpaced traditional manufacturing methods, leading to substantial efficiency gains in production rates. Recent industry reports indicate that CNC machining can increase production efficiency by up to 50% compared to conventional techniques. This shift is largely attributed to the automation and precision provided by CNC technology, which minimizes human error and maximizes repeatability. For example, leading manufacturers have reported reductions in cycle times and enhancements in overall throughput as a direct result of embracing CNC processes.

Moreover, the integration of modern metrology strategies within CNC machining environments has further refined production accuracy. Traditional measurement strategies often rely on labor-intensive methods that can introduce variances; however, innovations like Metrology 4.0 provide real-time data collection and analytics. These developments signify a trend where manufacturers can achieve up to a 40% improvement in measurement precision. As the demand for high-precision components increases in sectors such as aerospace and automotive, the need for robust, efficient manufacturing processes becomes paramount, making CNC machining the preferred choice for many modern factories.

Precision Engineering: How CNC Machining Reduces Tolerance Levels and Improves Quality

CNC machining has significantly transformed the landscape of precision engineering, enabling manufacturers to achieve unprecedented levels of accuracy and consistency in their projects. By utilizing computer numerical control technology, CNC machining streamlines the production process, meticulously executing complex designs with minimal tolerance levels. This capability not only enhances product quality but also reduces waste, as each component is crafted to exact specifications, resulting in fewer reworks and improved productivity.

Recent advancements in CNC machining technologies have further solidified its role in modern manufacturing. Companies are continuously pushing the boundaries of what is possible, integrating smart manufacturing principles to enhance operational efficiency. For instance, the introduction of specialized CNC machining capabilities for niche sectors, such as marine manufacturing, exemplifies how precision engineering is adapting to meet the unique demands of various industries. Such innovations ensure that manufacturers can maintain high quality standards while navigating the complexities of contemporary production environments. By embracing CNC machining, industries are setting new benchmarks in performance, quality, and operational excellence.

Economic Impact: Cost Savings Associated with CNC Machining in Large-Scale Production

According to a market research study published by Custom Market Insights, the global demand for CNC metal machining is on the rise, driven by an increasing need for precision and efficiency in manufacturing. CNC machining allows companies to produce complex metal parts with remarkable accuracy, significantly reducing the time and labor involved in traditional machining processes. As a result, organizations can achieve lower production costs while maintaining high-quality standards, which is particularly beneficial in large-scale manufacturing settings.

Moreover, the economic impact of CNC metal machining extends beyond direct cost savings. By streamlining production workflows and minimizing waste, businesses can optimize their resource utilization. This leads to enhanced operational efficiency, allowing manufacturers to respond more swiftly to market demands without sacrificing quality. The ability to produce large volumes of parts efficiently not only boosts profitability but also gives companies a competitive edge in an increasingly globalized market. The ongoing adoption of CNC technology signifies a pivotal shift towards more sustainable manufacturing practices, ensuring that industries remain resilient in the face of economic challenges.

Exploring the Impact of CNC Metal Machining on Modern Manufacturing Efficiency and Precision

| Metric | Value | Benefit/Cost Savings |

|---|---|---|

| Cycle Time Reduction | 25% | Faster turnaround time leads to increased production capacity. |

| Waste Reduction | 30% | Improved material usage lowers raw material costs. |

| Precision Improvement | ±0.01 mm | Higher precision reduces rework and scrap rates. |

| Energy Savings | 20% | Lower energy consumption decreases operational costs. |

| Labor Cost Reduction | 15% | Automation cuts down on manual labor expenses. |

| Return on Investment (ROI) | 150% | High ROI indicates financial benefits of CNC adoption. |

Future Trends: The Role of Automation and AI in Enhancing CNC Machining Efficiency

The integration of automation and artificial intelligence (AI) in CNC machining is revolutionizing modern manufacturing by enhancing efficiency and precision. AI-driven automation streamlines production processes, minimizing human error and optimizing operational workflows. This shift allows manufacturers to achieve higher output levels without compromising on quality, addressing the escalating demand for precision in various industries. The ability to analyze vast amounts of data in real-time enables manufacturers to implement predictive maintenance, reducing downtime and ensuring continuous operation.

Moreover, the role of AI in CNC machining extends beyond mere automation; it facilitates intelligent decision-making processes that adapt to changing production needs. As AI algorithms learn and evolve, they can optimize machining strategies, tool paths, and resource management, driving sustainability through reduced waste and energy consumption. The future landscape of manufacturing is poised to be defined by these innovations, paving the way for 'factories of the future' where efficiency and quality control are paramount, supported by the latest advancements in technology.

Impact of CNC Metal Machining on Manufacturing Efficiency and Precision

This chart illustrates the percentage increase in efficiency and precision in CNC metal machining over the last decade, highlighting the anticipated advancements due to automation and AI technologies by 2025.

Related Posts

-

Unmatched Excellence in Best CNC Metal from Leading Chinese Manufacturers

-

Exploring Innovative Alternatives to CNC Milling Machines for Your Manufacturing Needs

-

Unlocking Precision: The Future of CNC Metal Machining in Industry 4.0

-

Exploring Unique Features and Applications of Best CNC Manufacturing Solutions

-

Unlocking Precision: The Key Advantages of CNC Milling Machines for Modern Manufacturing

-

Ultimate Guide to Choosing the Perfect Home CNC Machine for Your Needs

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska