Unlocking the Power of CNC Turning Tips for Global Buyers in the Digital Era

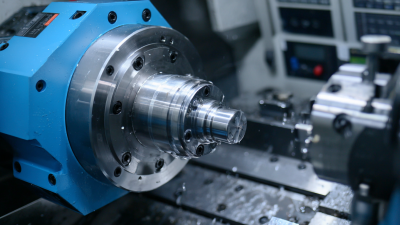

In the rapidly evolving landscape of modern manufacturing, CNC turning has emerged as a cornerstone technology, enabling precision engineering and efficiency that cater to the demands of global buyers. According to a report by ResearchAndMarkets, the CNC machine market is projected to reach $100 billion by 2025, driven by innovations in automation and smart manufacturing. This growth underscores the increasing reliance on CNC turning processes, which allow for the production of complex geometries with superior accuracy and repeatability. As industries seek to streamline operations and improve product quality, understanding the nuances of CNC turning becomes essential for buyers navigating this digital era. This guide aims to unlock the power of CNC turning, providing valuable insights and tips for making informed procurement decisions that align with global industry standards.

Understanding CNC Turning: Key Technologies and Innovations Shaping the Industry

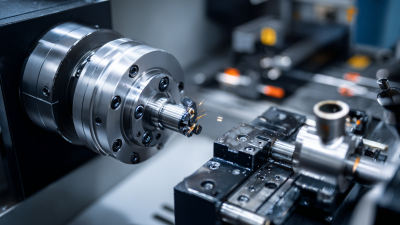

In the fast-evolving landscape of CNC turning, understanding key technologies and innovations is crucial for global buyers. The CNC turning industry is set to grow significantly, with projections indicating a rise in the woodworking machinery market from $5.23 billion in 2025 to $7.88 billion by 2032. This growth reflects a broader trend where advanced industrial software functions as the brain and nervous system of modern manufacturing, streamlining operations and enhancing efficiency.

To navigate this dynamic market, buyers should consider a few essential tips. First, staying informed about the latest CNC technologies can help in making educated purchasing decisions. Investing in modern CNC machines that integrate advanced software will not only improve precision but also boost productivity. Additionally, fostering strong relationships with reliable suppliers can provide insights into emerging trends and innovations, allowing buyers to stay ahead of the curve in a competitive marketplace. Embracing these strategies will ultimately unlock the full potential of CNC turning in the digital era.

Unlocking the Power of CNC Turning Tips for Global Buyers in the Digital Era

| Technology/Innovation | Description | Benefits | Market Impact |

|---|---|---|---|

| CNC Machine Automation | Integrating smart technologies for automatic operation. | Increased efficiency and reduced labor costs. | Allows manufacturers to scale production and reduce turnaround times. |

| Advanced Tooling | Utilizing high-speed cutting tools optimized for specific materials. | Better surface finishes and extended tool life. | Enhances competitiveness in precision machining markets. |

| 3D Printing Integration | Combining CNC turning with 3D printing capabilities. | Allows for the creation of complex geometries and rapid prototyping. | Expands design possibilities and reduces lead times. |

| IoT-Enabled Machines | CNC machines connected to the Internet for real-time data monitoring. | Improved maintenance schedules and operational transparency. | Leads to higher productivity and smarter decision-making. |

| Digital Twin Technology | Creating a virtual model of the CNC process for simulation and analysis. | Enhanced testing, troubleshooting, and optimization of processes. | Supports continuous improvement and innovation within the industry. |

Essential CNC Turning Tips: Maximizing Efficiency and Precision in Manufacturing

In the rapidly evolving landscape of manufacturing, CNC turning has emerged as a pivotal technology driving efficiency and precision. According to a report by Grand View Research, the global CNC machine market is expected to reach USD 100 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.6%. This surge highlights the critical need for global buyers to harness best practices in CNC turning to maintain competitive edges in their respective markets.

To maximize efficiency and precision in CNC turning, it’s essential to focus on tool selection and machine calibration. Recent studies show that using high-quality cutting tools can improve productivity by up to 30% while reducing waste. Additionally, regular calibration of CNC machines can lead to a 20% increase in operational consistency, minimizing variability in finished products. By adopting these essential tips, manufacturers not only enhance the quality of their output but also drive down operational costs, achieving substantial gains in profitability.

Navigating Global Suppliers: Best Practices for Choosing the Right CNC Turning Partners

Choosing the right CNC turning partners in today’s global marketplace requires a strategic approach. The digital era offers unprecedented access to suppliers from around the world, but this abundance of options can be overwhelming. Start by clearly defining your project requirements, including material specifications, tolerances, and production timelines. This clarity will help you narrow down potential partners who specialize in the necessary techniques and have a proven track record in delivering quality products.

Once you have a shortlist of suppliers, engage in thorough due diligence. Evaluate their experience, certifications, and customer reviews to gain insights into their capabilities and reliability. It’s also crucial to assess their communication practices; a responsive supplier who provides clarity during discussions can be an invaluable asset in ensuring smooth operations.

Consider requesting samples or small test runs to evaluate their production quality firsthand, which can further solidify your decision. By taking these steps, global buyers can confidently navigate the landscape of CNC turning suppliers and forge successful partnerships that drive innovation and efficiency.

Data-Driven Decision Making: Leveraging Analytics to Enhance CNC Turning Processes

In today’s digital era, data-driven decision making stands as a cornerstone for enhancing CNC turning processes. By harnessing the power of analytics, global buyers can gain invaluable insights into manufacturing efficiency, quality control, and supply chain management. Utilizing data analytics tools allows businesses to track performance metrics in real-time, identifying patterns that lead to constant improvement. For instance, monitoring machine uptime and cycle times can highlight areas requiring maintenance or optimization, thereby minimizing downtime and reducing costs.

Moreover, leveraging data can significantly enhance customization and responsiveness in CNC turning. By analyzing customer feedback and market trends, manufacturers can adapt their production processes to meet changing demands swiftly. This agility not only increases customer satisfaction but also positions businesses competitively in the market. Implementing predictive analytics ensures that manufacturers can anticipate future trends and prepare for fluctuations in demand, thus unlocking further potential in CNC operations. In this fast-paced environment, data-driven insights empower buyers to make informed choices that optimize overall operational performance.

Unlocking the Power of CNC Turning: Efficiency Metrics

Future Trends in CNC Turning: Predictions and Opportunities in a Digitalized Market

As the global CNC turning market is poised to experience substantial growth, predicted to escalate from a value of $10.12 billion in 2025 to a staggering $19.559 billion by 2032, it is crucial for buyers to stay abreast of emerging trends. The compound annual growth rate (CAGR) of 9.9% during this forecast period indicates that digital innovation is fundamentally reshaping the landscape of CNC manufacturing. Companies are expected to harness advanced technologies such as artificial intelligence and machine learning, which will enhance precision, efficiency, and customization in CNC turning operations.

Furthermore, the shift toward digitalization presents numerous opportunities for buyers in the CNC machining sector. With increasing demand for high-quality components across various industries—ranging from automotive to aerospace—global buyers must leverage data analytics and integrated solutions to ensure they remain competitive. Investing in smart CNC technologies not only streamlines production processes but also enables businesses to respond proactively to market fluctuations. As the market continues to evolve, adopting a forward-thinking approach will be essential for identifying prospects and maximizing returns on investment.

Related Posts

-

Unlocking Efficiency and Precision with Best CNC Manufacturing Solutions

-

Setting the Gold Standard: Industry Production Guidelines for the Best CNC Lathes

-

Exploring Innovative Alternatives to CNC Milling Machines for Your Manufacturing Needs

-

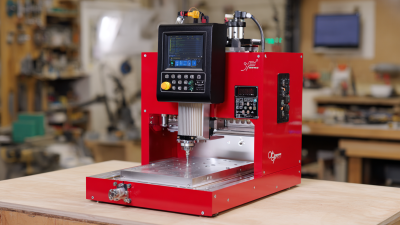

Navigating the 2025 Technology Trends with the Best Small CNC Machine for Metal

-

Global Sourcing Chinese Excellence: Why the Best CNC Lathe Machines Dominate World Markets

-

The Future of Precision Engineering: Revolutionizing Manufacturing with the Best Desktop CNC Mills

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska