Unlocking Efficiency and Precision with Best CNC Manufacturing Solutions

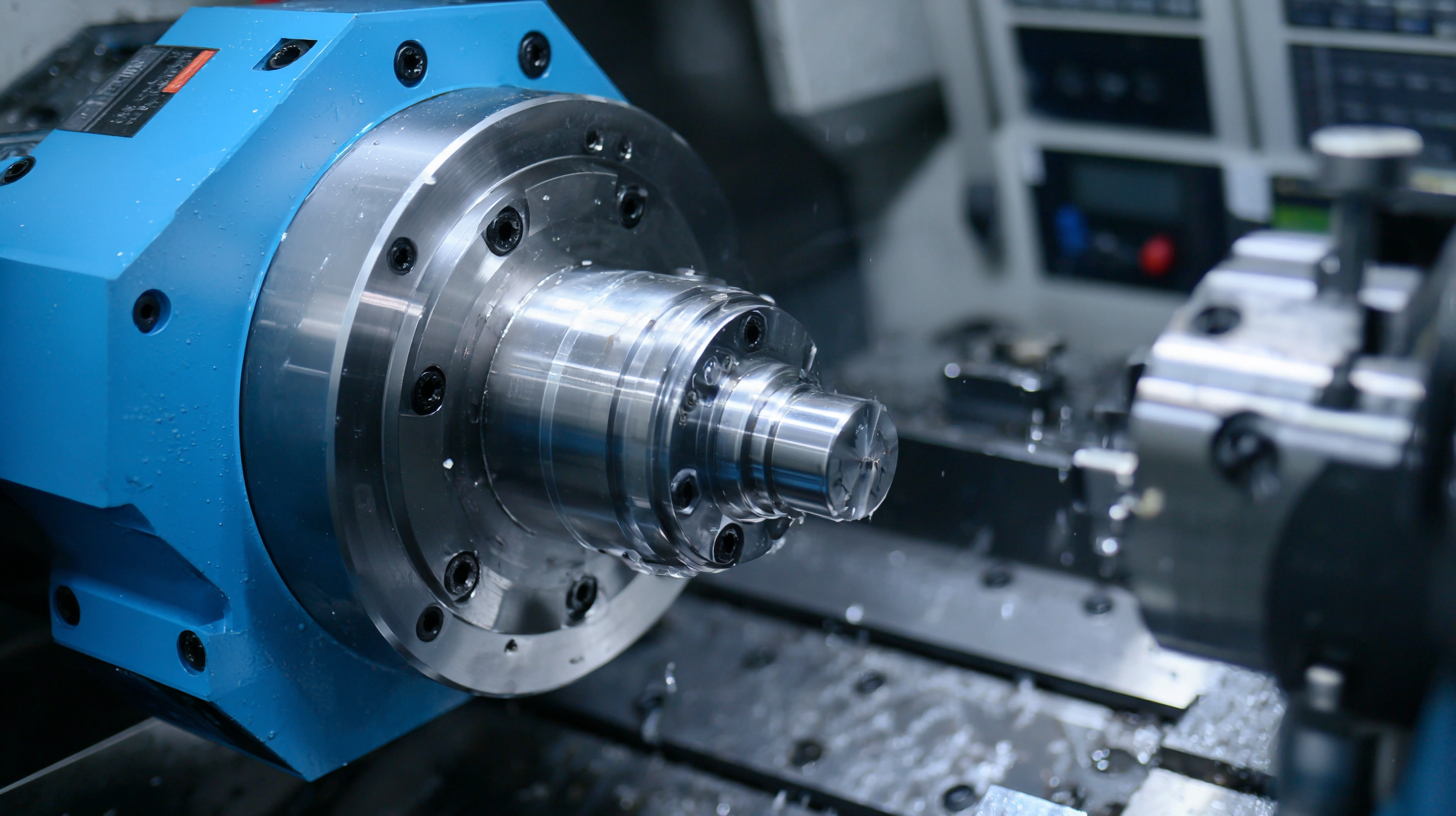

In the rapidly evolving landscape of modern manufacturing, CNC manufacturing has emerged as a pivotal solution for enhancing efficiency and precision across various industries. With the global computer numerical control (CNC) machine market projected to reach approximately $100 billion by 2025, driven by the demand for high-quality and customizable products, businesses are increasingly turning to sophisticated CNC manufacturing solutions.

These solutions cater to a diverse array of products, each with unique characteristics and applications, ranging from intricate aerospace components to robust automotive parts. As organizations strive to meet the growing consumer expectations for tailored and reliable products, selecting the right CNC manufacturing process becomes crucial.

This blog will explore the different types of CNC manufacturing alternatives, their specific advantages, and how they align with various product requirements, ultimately unlocking unparalleled efficiency and precision in production.

Overview of CNC Manufacturing Solutions: Types and Applications

In the realm of CNC manufacturing solutions, understanding the different types and applications is essential for unlocking efficiency and precision. The trade promotion management and optimization solutions market is projected to grow from $739.77 million in 2024 to $1.46983 billion by 2032, reflecting a robust CAGR of 8.96%. This growth underscores the increasing importance of optimized manufacturing processes in enhancing operational effectiveness.

Another noteworthy sector is the industrial control systems security market, forecasted to expand from $17.40113 billion in 2020 to $29.190 billion by 2029, showcasing a CAGR of 8.92%. This vigilance in securing control systems is crucial, particularly as industries adopt more sophisticated CNC technologies that intersect with digital systems.

**Tips:** Ensure that your CNC operations leverage the latest software solutions to maintain security against evolving threats. Additionally, investing in training programs for your workforce can significantly improve the implementation and utility of these advanced manufacturing technologies. Staying informed on market trends and technological advancements will not only keep your operations running smoothly but also enhance your competitive edge in the industry.

Unlocking Efficiency and Precision with Best CNC Manufacturing Solutions

| CNC Manufacturing Solution | Type | Applications | Material Compatibility | Precision Level |

|---|---|---|---|---|

| CNC Milling | Subtractive Manufacturing | Parts manufacturing, mold making | Metal, plastic, wood | 0.005 mm |

| CNC Turning | Subtractive Manufacturing | Shafts, bushings | Metal, plastic | 0.01 mm |

| CNC Laser Cutting | Subtractive Manufacturing | Sheet metal fabrication | Metal, plastic, wood | 0.1 mm |

| CNC Routers | Subtractive Manufacturing | Sign making, cabinetry | Wood, plastic | 0.025 mm |

| CNC Waterjet Cutting | Subtractive Manufacturing | Complex shapes, hard materials | Metal, glass, stone | 0.5 mm |

Key Features to Compare in CNC Machines: Speed, Accuracy, and Cost

When comparing CNC machines, three key features stand out: speed, accuracy, and cost. Speed is crucial for production efficiency; high-speed machining reduces cycle times and increases throughput. However, it's essential to balance speed with accuracy. At higher speeds, the dynamic error can often surpass the quasi-static error, leading to compromised machining precision. Therefore, selecting machines that maintain accuracy even at elevated speeds is vital for quality output.

Accuracy directly impacts the final product's quality, making it a top priority in CNC operations. Look for CNC systems specifically designed to minimize dynamic errors during high-speed operations. Investing in machines that offer advanced error compensation features can significantly enhance precision and reduce waste, ensuring that projects meet stringent specifications.

Cost is always a factor. While the initial investment in high-quality CNC machines may be significant, it's essential to consider the long-term savings associated with reduced waste, improved efficiency, and less downtime. When evaluating potential options, keep an eye on the total cost of ownership, which includes maintenance and operating expenses over the machine's lifespan.

Tips: Always conduct a thorough assessment of your machining needs before purchasing a CNC machine. This ensures that you select a model that aligns with your specific production volume and precision requirements. Additionally, don’t underestimate the value of regular training for your operators to maximize the capabilities of your CNC technology.

Evaluating CNC Software: User Interface, Compatibility, and Features

When evaluating CNC software, the user interface plays a crucial role in determining the overall efficiency and precision of manufacturing operations. A well-designed user interface simplifies navigation and gives operators immediate access to essential functions, thereby reducing the learning curve and improving productivity. Intuitive layouts, customizable dashboards, and clear visual aids empower users to optimize their workflows, ensuring that even complex tasks can be executed with ease.

Another critical factor to consider is compatibility with various CNC machines and other software tools. Effective CNC manufacturing solutions must seamlessly integrate with existing systems to facilitate smooth communication across platforms. This compatibility not only enhances the functionality of the equipment but also saves time and resources by minimizing the need for additional training or software replacements. Furthermore, robust features such as advanced simulation capabilities, real-time monitoring, and powerful analytics can significantly elevate the operational performance, allowing manufacturers to fine-tune their processes and achieve unprecedented levels of precision.

Evaluating CNC Software: User Interface, Compatibility, and Features

Material Compatibility in CNC Machining: Best Practices for Different Materials

When it comes to CNC machining, understanding material compatibility is crucial for achieving optimal results. Different materials, such as metals, plastics, and composites, exhibit varying properties that can significantly affect the machining process. For instance, harder materials like titanium require specialized tools and slower feed rates to prevent tool wear and ensure precision. Conversely, softer materials such as aluminum are more forgiving and allow for quicker machining without sacrificing quality. By choosing the appropriate settings and tools based on the material type, manufacturers can improve efficiency and avoid costly mistakes.

Best practices in CNC machining also involve considering the thermal properties of materials. Certain plastics can deform under high temperatures, making it essential to manage cutting speeds and tool selections carefully. Additionally, materials like carbon fiber require specific drill bits to prevent fraying and delamination during the process. Understanding these nuances not only enhances the precision of the final product but also extends the lifespan of both tools and machinery. By prioritizing material compatibility, manufacturers can unlock new levels of efficiency and quality in their CNC machining endeavors.

Case Studies: Success Stories with Top CNC Manufacturing Solutions

In the world of CNC manufacturing, choosing the right solution can dramatically enhance productivity and precision. Case studies from leading companies reveal how adopting advanced CNC technologies has transformed their operations. For instance, a major aerospace manufacturer implemented a state-of-the-art CNC milling machine that increased their production speed by 30%, all while maintaining unparalleled accuracy for complex components. This investment not only streamlined their manufacturing processes but also significantly reduced waste, showcasing the undeniable impact of top-tier CNC solutions.

Another compelling case is from an automotive parts supplier that integrated CNC technology into their assembly line. By utilizing smart CNC systems with real-time monitoring, they identified inefficiencies and adjusted their workflows accordingly. As a result, they experienced a reduction in lead time by 25%, allowing them to meet tighter production schedules without compromising quality. These success stories illustrate that the right CNC manufacturing solutions can unlock efficiency and precision, driving innovation and competitive advantage in various industries.

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska