Setting the Gold Standard: Industry Production Guidelines for the Best CNC Lathes

As the manufacturing landscape evolves toward 2025, the need for stringent production guidelines in the CNC lathe industry has never been more critical. According to a recent report by MarketsandMarkets, the global CNC lathe market is projected to reach USD 2.77 billion by 2025, with a compound annual growth rate (CAGR) of 6.2% from 2020 to 2025. This growth is fueled by increasing automation in manufacturing processes and the rising demand for precision engineering. As manufacturers strive to meet these demands, adhering to industry production guidelines is essential for optimizing performance, enhancing precision, and ensuring the longevity of CNC lathes. This blog will delve into the key trends shaping the CNC lathe industry and provide a comprehensive checklist to help industry professionals set the gold standard in production practices.

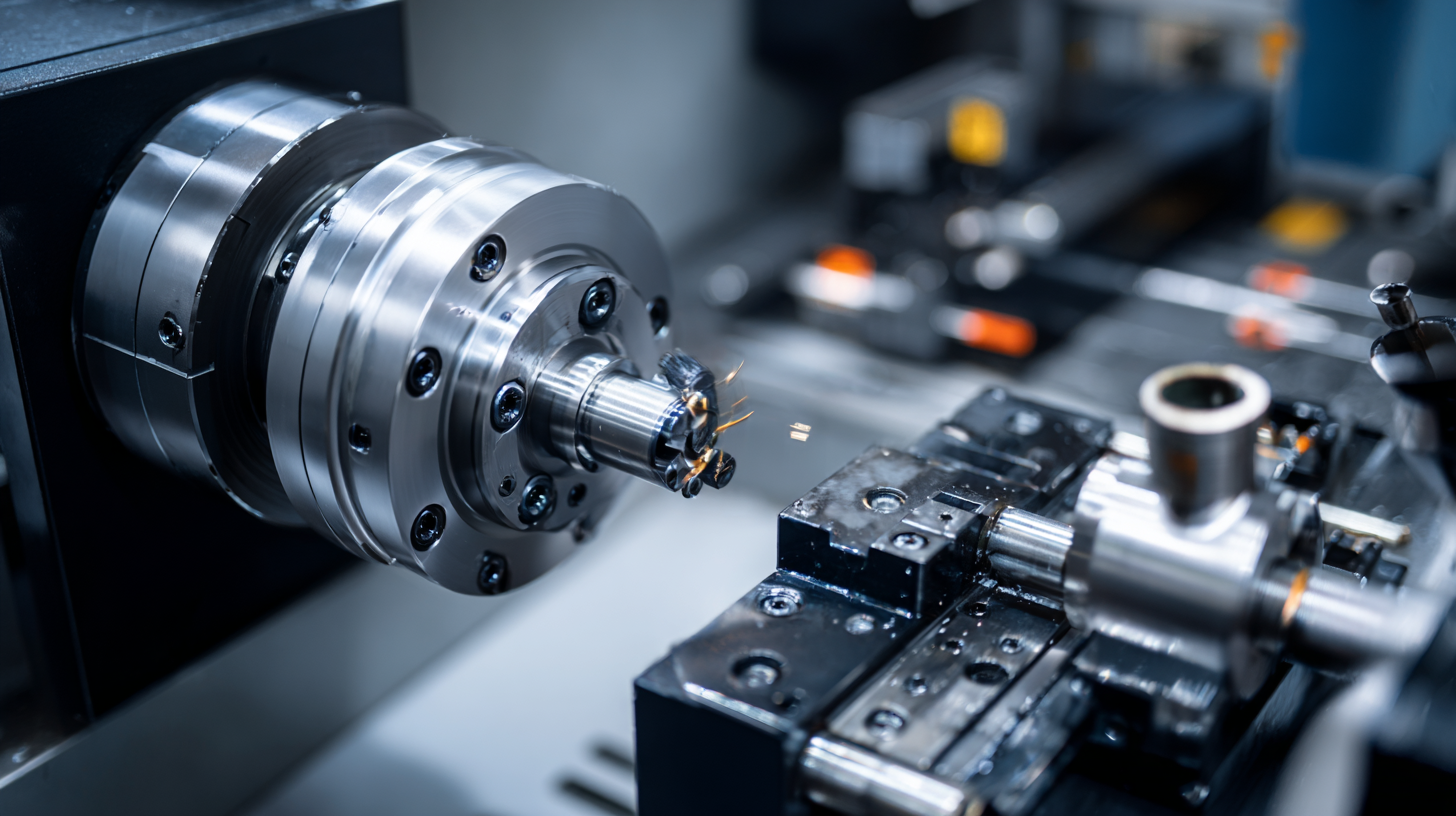

Understanding CNC Lathe Basics: Key Features and Specifications

When exploring the fundamentals of CNC lathes, it is crucial to understand their key features and specifications. CNC lathes are distinguished by their ability to perform precise rotational operations, which is pivotal in achieving high-quality finishes across various materials. For instance, the implementation of digital twin technology in modern CNC machining allows for real-time simulation and optimization, enhancing overall production efficiency. These digital replicas of physical machines can significantly reduce downtime and maintenance costs, which is essential for manufacturers looking to stay competitive.

Moreover, specifications such as spindle speed, tool change speed, and axes movement play integral roles in a CNC lathe's performance. Industry reports indicate that CNC systems equipped with advanced spindle units can achieve speeds exceeding 10,000 RPM, catering to a broader range of materials and applications. Additionally, features such as energy-efficient operation and integration with existing systems can greatly influence production sustainability and cost-effectiveness. As manufacturers increasingly prioritize eco-friendly practices, CNC lathes that optimize these aspects not only improve output but also contribute to reduced carbon footprints, positioning them as more than just tools, but as pivotal components of modern manufacturing strategies.

Top 5 Industry Standards in CNC Lathe Production Guidelines

The manufacturing landscape has been revolutionized by the integration of advanced digital technologies, leading to significant enhancements in the productivity and capabilities of CNC lathes. As industries strive to maintain competitive advantages, adherence to established production guidelines becomes crucial. These standards ensure that CNC lathes deliver optimal performance, precision, and reliability, which are the cornerstones of successful manufacturing processes.

Among the top five industry standards in CNC lathe production guidelines are specifications for materials, tooling, and programming practices. Proper material selection not only influences the quality of the final product but also impacts the tooling life span and maintenance requirements. Additionally, employing the latest programming techniques enhances machine efficiency and minimizes waste, aligning perfectly with the goal of sustainable manufacturing. As manufacturers continue to adopt these standards, they are not just improving their operational outcomes but also setting benchmarks for excellence within the industry.

Setting the Gold Standard: Industry Production Guidelines for the Best CNC Lathes - Top 5 Industry Standards in CNC Lathe Production Guidelines

| Standard | Description | Criteria | Importance Level |

|---|---|---|---|

| Precision Machining | Ensures high tolerances for parts | ±0.01 mm | High |

| Material Quality | Use of high-grade raw materials | High strength steel or aluminum | Critical |

| Machine Calibration | Regular calibration of CNC machines | Quarterly checks | High |

| Safety Standards | Compliance with industry safety regulations | ISO 45001 | Essential |

| Process Optimization | Efficient manufacturing processes to reduce waste | Lean Manufacturing principles | High |

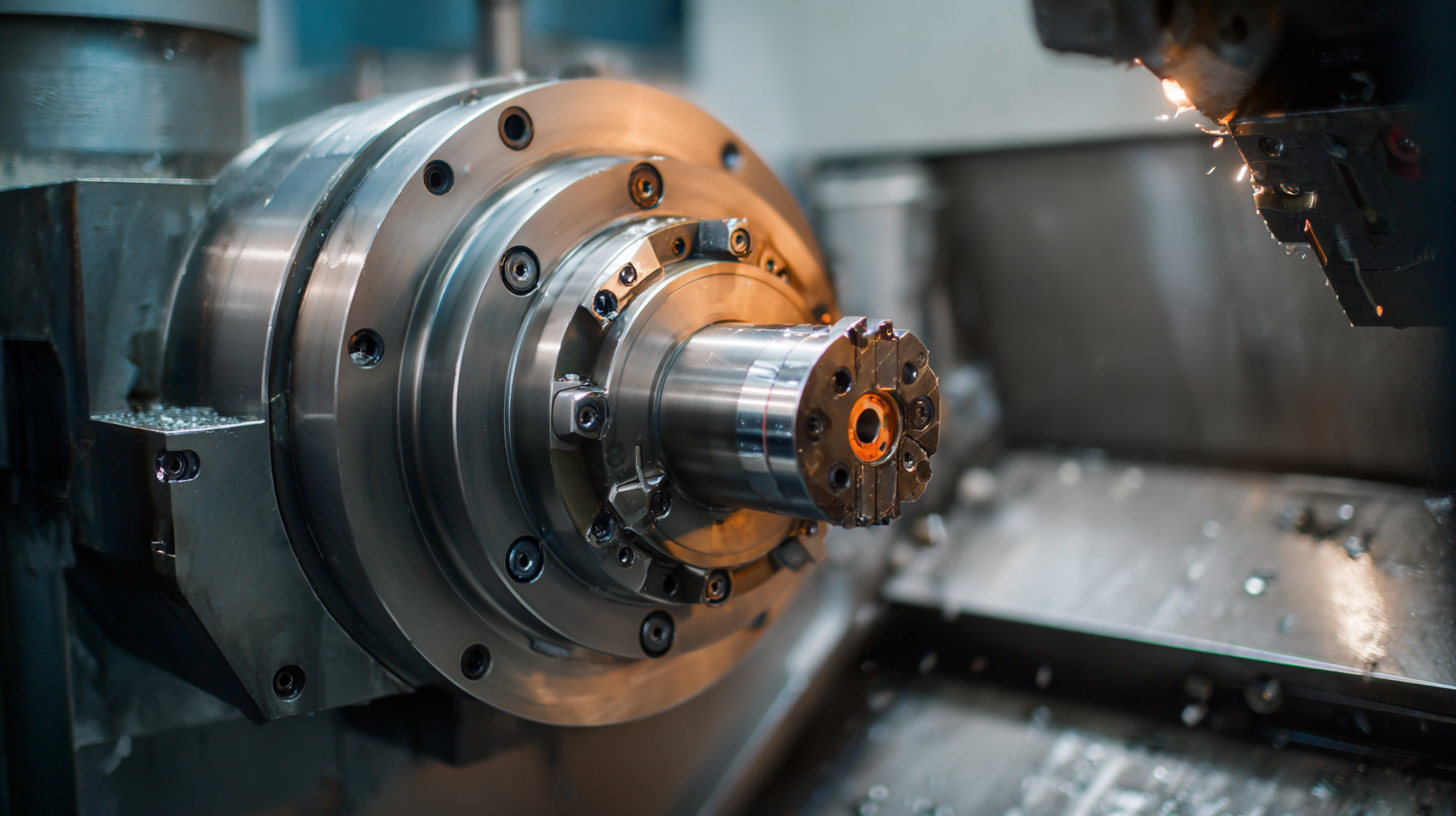

Choosing the Right CNC Lathe: Factors to Consider for Quality

When selecting the right CNC lathe for your production needs, several factors come into play that can significantly impact the quality of your machining processes. First and foremost, consider the machine's rigidity and stability. A robust CNC lathe minimizes vibrations, ensuring precision in machining operations and prolonging tool life. Look for models that feature solid construction and high-quality materials, as these will provide the necessary foundation for achieving tight tolerances.

Another critical factor is the control system of the CNC lathe. A user-friendly interface with advanced features, such as precise programming options and real-time monitoring capabilities, can enhance productivity and ease of use. Additionally, assessing the available tooling options and compatibility with various materials will ensure that the lathe can adapt to your specific machining requirements. By examining these factors thoroughly, you can choose a CNC lathe that not only meets technical specifications but also boosts your overall production efficiency.

Maintenance Tips: Keeping Your CNC Lathe in Peak Condition

Maintaining a CNC lathe in peak condition is essential for optimal performance and longevity. Regular maintenance not only enhances the precision and efficiency of the machine but also prevents costly downtime. One key aspect of maintenance is routine lubrication. Ensure that all moving parts are properly lubricated with the manufacturer-recommended fluids. This practice reduces friction, minimizes wear, and keeps the lathe running smoothly.

Another vital maintenance tip is to keep the machine clean. Dust, chips, and coolant residue can accumulate and interfere with the machining process. Regularly clean the work area and components, including the spindle, tool post, and bed, to maintain a tidy environment that supports high-precision work. Additionally, regularly checking and calibrating the machine’s alignment and settings will help catch any issues before they escalate into major problems. By incorporating these practices into a consistent maintenance routine, operators can ensure their CNC lathes remain reliable and perform at their best for years to come.

Maintenance Tips for CNC Lathes

The Future of CNC Lathes: Innovations Shaping the Industry Standards

The landscape of CNC lathes is rapidly evolving, driven by advancements in technology and the increasing demand for precision in manufacturing. With a century-long history, CNC (Computer Numerical Control) machines have become indispensable in various industries, allowing manufacturers to achieve high levels of automation and efficiency. According to a recent industry report, the global CNC machine market is projected to reach approximately $100 billion by 2026, reflecting a compound annual growth rate (CAGR) of around 7.5% from 2021 to 2026. This growth can be attributed to the adoption of innovative features such as IoT connectivity and advanced materials.

Innovations shaping the future of CNC lathes primarily focus on enhancing operational efficiency and flexibility. The integration of artificial intelligence (AI) and machine learning into CNC systems is enabling real-time monitoring and predictive maintenance, reducing downtime significantly. Furthermore, the rise of additive manufacturing techniques is being integrated with traditional CNC processes, allowing for hybrid machining solutions that enhance functionality and reduce production waste. As the industry pushes towards Industry 4.0, the ability to adapt and implement these cutting-edge technologies will set the gold standard for CNC lathe production, paving the way for higher precision and better quality assurance in manufacturing processes.

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska