Exploring Innovative Use Cases of Small CNC Machines for Metal Fabrication

In the realm of modern metal fabrication, the advent of technology has revolutionized how artisans and engineers approach their craft. Among these advancements, the small CNC machine for metal stands out as a game-changer, offering unparalleled precision and versatility in a compact form. This blog post will delve into innovative use cases of small CNC machines, exploring how they can elevate projects ranging from intricate prototypes to personalized components. Whether you're a hobbyist looking to enhance your workspace or a professional seeking to optimize production processes, understanding the potential applications of these machines is essential. Join us as we uncover the myriad possibilities that small CNC machines bring to the world of metal fabrication, providing you with practical insights and inspiration to harness their capabilities in your projects.

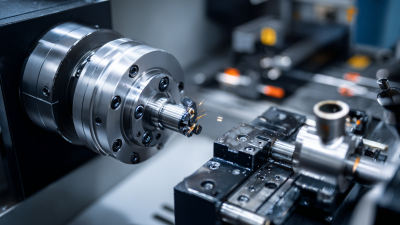

Innovative Small CNC Machines: Redefining Metal Fabrication Techniques

The advent of small CNC machines is revolutionizing metal fabrication techniques, enabling a new wave of innovation across various industries. With smaller, more affordable CNC machines, companies can now streamline their production processes, allowing for precision engineering that was previously reserved for larger enterprises. Reports suggest that the global small CNC machine market is projected to surpass $5 billion by 2026, driven by the increasing demand for customization in manufacturing. This technological shift is not only enhancing efficiency but also fostering creativity in design, particularly in sectors such as medical devices, where bespoke parts are essential for advancing healthcare solutions.

The advent of small CNC machines is revolutionizing metal fabrication techniques, enabling a new wave of innovation across various industries. With smaller, more affordable CNC machines, companies can now streamline their production processes, allowing for precision engineering that was previously reserved for larger enterprises. Reports suggest that the global small CNC machine market is projected to surpass $5 billion by 2026, driven by the increasing demand for customization in manufacturing. This technological shift is not only enhancing efficiency but also fostering creativity in design, particularly in sectors such as medical devices, where bespoke parts are essential for advancing healthcare solutions.

As industries evolve, the significance of metal fabrication in innovation cannot be overlooked. The COVID-19 pandemic highlighted the critical role technology plays, with rapid prototyping and production helping to meet urgent demands for medical equipment and devices. Emerging manufacturing startups are at the forefront of this transformation, utilizing small CNC machines to produce intricate components that facilitate innovation in medical technology. As China continues to bolster its position as a leader in advanced industries, harnessing the potential of small CNC machines will be pivotal in maintaining competitive advantage and driving forward-thinking solutions that impact both domestic and global markets.

Versatile Applications: From Prototyping to Mass Production in Metalworks

The versatility of small CNC machines in metal fabrication has revolutionized the industry, enabling applications that range from rapid prototyping to large-scale production. According to a report by MarketsandMarkets, the global CNC machine market is projected to grow to $117 billion by 2025, driven largely by advancements in automation and the rising demand for precision engineering. Small CNC machines, with their ability to deliver high-quality results at a lower cost, are at the forefront of this trend, making them ideal for small businesses and startups that require both flexibility and efficiency.

The versatility of small CNC machines in metal fabrication has revolutionized the industry, enabling applications that range from rapid prototyping to large-scale production. According to a report by MarketsandMarkets, the global CNC machine market is projected to grow to $117 billion by 2025, driven largely by advancements in automation and the rising demand for precision engineering. Small CNC machines, with their ability to deliver high-quality results at a lower cost, are at the forefront of this trend, making them ideal for small businesses and startups that require both flexibility and efficiency.

One key application of small CNC machines is in prototyping. These machines allow engineers to create precise models quickly, which accelerates the development process. This is critical in industries such as automotive and aerospace, where rapid innovation is essential. A tip for maximizing efficiency in prototyping is to invest in robust CAM software that can seamlessly integrate with CNC machine operations, ensuring smooth transitions from design to production.

In addition to prototyping, small CNC machines are also increasingly utilized for mass production in metalworks. The ability to produce customized parts with minimal setup time makes them a valuable asset in both low-volume and high-volume manufacturing. To optimize production, consider implementing lean manufacturing principles. This approach helps reduce waste and improve overall efficiency, making the most of your CNC capabilities while meeting the demands of diverse clientele.

Enhancing Precision: The Role of Small CNCs in Fine-Tuning Metal Designs

Small CNC machines have emerged as essential tools in the realm of metal fabrication, playing a critical role in enhancing precision and fine-tuning intricate designs. With their ability to execute complex cuts and shapes, these machines enable fabricators to achieve levels of accuracy that were once reserved for larger, more expensive equipment. This newfound precision allows for the creation of highly detailed components, whether for automotive applications or artistic metal sculptures.

Tips for achieving optimal results with small CNCs include ensuring that your tooling is appropriate for the materials you are working with. Using sharp, quality bits can drastically improve the finish of your cuts. Additionally, taking the time to calibrate your machine and perform routine maintenance will help maintain its accuracy. Don’t overlook the importance of the design software; a well-prepared CAD model can greatly facilitate the machining process and minimize errors.

Furthermore, experimenting with feed rates and cutting speeds can lead to enhanced precision. Slower speeds may yield finer details, while optimized feed rates can significantly improve productivity without sacrificing quality. Keep a detailed log of your settings and outcomes; it's an invaluable resource for future projects and helps in refining your processes over time.

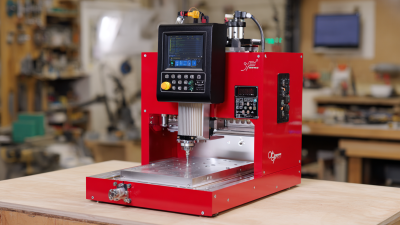

Cost-Effective Solutions: How Small CNC Machines Are Making Fabrication Affordable

The rise of small CNC machines has revolutionized metal fabrication, providing a cost-effective solution for both hobbyists and small businesses. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $100.1 billion by 2026, with a significant portion driven by the increasing adoption of compact CNC machines. These machines not only reduce upfront costs but also operational expenses, allowing startups to enter the market with less financial strain.

One of the standout benefits of small CNC machines is their versatility. They enable users to perform intricate machining tasks without the need for substantial floor space or investment. A study from Grand View Research indicates that small CNC machinery can cut costs by as much as 30% when compared to traditional manufacturing methods. This affordability opens doors for innovators and craftspeople to turn their ideas into reality.

**Tip:** When considering a small CNC machine, assess your specific fabrication needs to ensure you select a model that balances capability with cost. **Tip:** Regular maintenance and software updates can significantly enhance the performance and longevity of your CNC machine, minimizing downtime and additional costs. **Tip:** Explore online resources and communities dedicated to CNC machining for valuable insights on optimization and best practices in metal fabrication.

Exploring Innovative Use Cases of Small CNC Machines for Metal Fabrication - Cost-Effective Solutions

| Use Case | Material | Cost Savings (%) | Time Efficiency (hrs) |

|---|---|---|---|

| Prototype Development | Aluminum | 30% | 5 |

| Custom Tooling | Steel | 25% | 7 |

| Artwork Engraving | Brass | 40% | 3 |

| Replacement Parts | Plastic | 20% | 4 |

| Miniature Models | Titanium | 35% | 6 |

Integrating Technology: The Future of Smart Manufacturing with Small CNC Machines

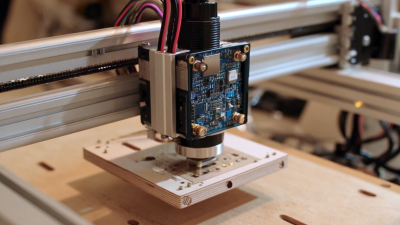

The manufacturing landscape is rapidly evolving with the integration of smart technology, and small CNC machines are at the forefront of this revolution. These compact, precise tools are not just transforming traditional metal fabrication; they are paving the way for more efficient, agile production processes. By incorporating advanced technologies such as IoT and AI, small CNC machines can now communicate with other devices, optimize workflows, and reduce downtime. This level of connectivity allows for real-time monitoring and adjustments, leading to higher quality control and lower operational costs.

Moreover, the integration of smart technology with small CNC machines is fostering greater accessibility for small businesses and individual makers. With user-friendly interfaces and cloud-based software, even those without extensive engineering backgrounds can leverage CNC technology to create intricate metal parts. As a result, we are witnessing a democratization of manufacturing where innovation thrives in smaller workshops and home-based operations. The synergy between small CNC machines and smart manufacturing not only enhances production capabilities but also inspires a new wave of creativity, enabling innovators to turn their ideas into reality more efficiently than ever before.

Related Posts

-

Global Sourcing Chinese Excellence: Why the Best CNC Lathe Machines Dominate World Markets

-

Setting the Gold Standard: Industry Production Guidelines for the Best CNC Lathes

-

Exploring Innovative Alternatives to CNC Milling Machines for Your Manufacturing Needs

-

Digital Revolution in Manufacturing Discover the Best Router CNC for Your Needs

-

Navigating the 2025 Technology Trends with the Best Small CNC Machine for Metal

-

Exploring the Future of Best Milling Machines in 2025 Industry Trends and Innovations

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska