Unlocking Precision: The Key Advantages of CNC Milling Machines for Modern Manufacturing

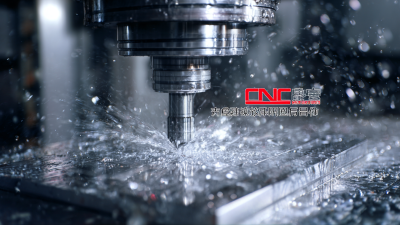

In the rapidly evolving landscape of modern manufacturing, precision and efficiency are paramount, and the CNC milling machine stands at the forefront of this transformation. This advanced technology automates the milling process, allowing businesses to produce intricate designs with minimal human intervention while significantly reducing the risk of error. The versatility of CNC milling machines makes them indispensable across various industries, from aerospace to consumer electronics. In this blog post, we will explore how to harness the full potential of CNC milling machines, highlighting their key advantages, including enhanced accuracy, improved productivity, and the ability to create complex geometries that were once deemed impractical. Join us as we unlock the precision these machines offer and discover how they can revolutionize your manufacturing processes.

Understanding CNC Milling: A Game Changer in Modern Manufacturing

CNC milling has emerged as a game changer in modern manufacturing, significantly enhancing precision and efficiency in production processes. According to a report by Research and Markets, the global CNC machinery market is expected to reach $100 billion by 2025, with CNC milling leading the charge due to its versatility and effectiveness in producing complex components. This technology enables manufacturers to achieve tolerances as tight as ±0.001 inches, which is crucial for industries such as aerospace and medical devices where precision is paramount.

For optimal results with CNC milling, consider investing in high-quality cutting tools. A study from Technavio indicates that the right tooling can enhance the lifespan and efficiency of CNC machines, reducing operational costs by an estimated 15%. Additionally, regular maintenance of the machine, including calibration and software updates, can prevent costly downtimes and ensure consistent output quality.

Another tip for manufacturers is to leverage simulation software before actual machining. This can help identify potential design flaws and allows for adjustments in programming, cutting down on material waste by as much as 20%, as reported by the National Association of Manufacturers. By integrating these strategies, companies can fully harness the transformative power of CNC milling technology.

Unlocking Precision: The Key Advantages of CNC Milling Machines for Modern Manufacturing

| Feature | Advantage | Application |

|---|---|---|

| High Precision | Produces complex parts with tight tolerances | Aerospace components manufacturing |

| Automation | Reduces human error and increases production speed | Automotive parts fabrication |

| Versatility | Capable of milling, drilling, tapping, and more | Custom machinery and fixtures |

| Cost-Effectiveness | Minimizes waste material and time | Production of small and medium batches |

| Material Compatibility | Works with a wide range of materials | Manufacturing of medical devices |

Top 5 Benefits of CNC Milling Machines for Increased Production Efficiency

CNC milling machines are revolutionizing modern manufacturing by offering unparalleled precision and efficiency. As the global CNC machines market is projected to grow significantly, reaching USD 170.4 billion by 2033, manufacturers are increasingly recognizing the advantages of adopting these advanced technologies. The rise in demand for high-precision and multi-axis machining centers underscores the need for tools that can handle complex tasks with utmost accuracy.

One of the primary benefits of CNC milling machines is their ability to enhance production efficiency. These machines allow for the automation of tasks that once required extensive manual labor, thereby reducing the likelihood of human error and increasing throughput. Additionally, with the integration of AI and digital twin technology, the CNC machining process can be further optimized, ensuring that operations are streamlined and costs are controlled. This sophisticated interplay between real and digital environments enables manufacturers to achieve a "first time right" approach, significantly boosting overall productivity. The continual evolution of CNC technology promises to redefine the manufacturing landscape, making it essential for businesses to embrace these advancements to stay competitive.

Unlocking Precision: The Key Advantages of CNC Milling Machines for Modern Manufacturing

How CNC Milling Enhances Precision and Reduces Errors in Manufacturing

CNC milling machines are revolutionizing the manufacturing landscape by enhancing precision and significantly reducing errors. The integration of computer numerical control technology allows for intricate designs and consistent production quality that surpasses traditional machining methods. Operators can create complex components with unparalleled accuracy, minimizing human error and ensuring that each part meets exact specifications. This level of precision is critical in industries where even the slightest deviation can lead to costly failures or safety hazards.

Moreover, as the demand for high-precision and efficient manufacturing processes grows, CNC milling machines are evolving to accommodate these needs. Recent advancements in digital manufacturing technologies have propelled the CNC machine market, allowing vendors to transition from conventional operations to automated solutions. This shift not only boosts productivity but also addresses the increasing focus on environmental sustainability with the rise of eco-friendly machine options. By leveraging these innovations, manufacturers can achieve enhanced operational efficiency while delivering high-quality results that meet the rigorous demands of today's market.

The Role of CNC Milling in Streamlining Complex Design Processes

CNC milling machines play a pivotal role in modern manufacturing, especially when it comes to navigating the intricate landscape of complex design processes. By leveraging advanced computer numerical control technology, these machines automate the precision cutting and shaping of materials, achieving results that were once considered unattainable. This automation significantly reduces human error, enhances consistency, and accelerates production timelines, allowing manufacturers to bring sophisticated designs to life with remarkable accuracy.

CNC milling machines play a pivotal role in modern manufacturing, especially when it comes to navigating the intricate landscape of complex design processes. By leveraging advanced computer numerical control technology, these machines automate the precision cutting and shaping of materials, achieving results that were once considered unattainable. This automation significantly reduces human error, enhances consistency, and accelerates production timelines, allowing manufacturers to bring sophisticated designs to life with remarkable accuracy.

Moreover, the versatility of CNC milling enables designers and engineers to experiment with innovative shapes and structures. With the capability to execute intricate patterns and fine details, it empowers teams to explore creative solutions without the constraints often imposed by traditional manufacturing methods. This not only fosters innovation but also streamlines the prototyping phase, turning conceptual visions into tangible products faster than ever before. As industries continue to evolve, the integration of CNC milling in creating complex designs demonstrates its essential role in driving progress and efficiency in manufacturing.

Cost-Effectiveness: Why CNC Milling Machines Are Worth the Investment

CNC milling machines have become a cornerstone of modern manufacturing, offering a slew of cost-effective benefits that make them a worthwhile investment. The global CNC machine market is projected to grow significantly, from $101.22 billion in 2025 to $195.59 billion by 2032, reflecting the increasing demand for precision and efficiency in machining processes. One key advantage is their ability to produce intricate designs with high accuracy, thereby minimizing material waste and reducing overall production costs.

Moreover, advancements in technology have enabled the incorporation of smart features and automation, enhancing productivity. Manufacturers can achieve consistent results across large production runs while also reducing manual labor. Recent studies highlight the critical role of tool holders within CNC processes, further emphasizing the importance of investing in quality machinery. As industries continue to transition towards more sustainable and efficient practices, CNC milling machines stand out as a valuable asset, driving innovation and cost savings in the manufacturing landscape.

Related Posts

-

Exploring Innovative Alternatives to CNC Milling Machines for Your Manufacturing Needs

-

Unmatched Excellence in Best CNC Metal from Leading Chinese Manufacturers

-

7 Innovative Best CNC Milling Techniques You Should Know About Today

-

The Future of Advanced CNC Machine Technologies in Global Manufacturing

-

Discovering the Advantages of the Best Smart CNC Technology for Modern Manufacturing

-

Discover Superior Manufacturing with the Best Desktop CNC Mill from Top Chinese Factories

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska