Mastering Precision with Small CNC Lathes for Your Next Project

In the realm of precision machining, the use of small CNC lathes has revolutionized the way craftsmen approach their projects. According to a report by Research and Markets, the global CNC lathe market is projected to grow at a compound annual growth rate (CAGR) of 6.15% from 2021 to 2026, underscoring the increasing demand for high-quality, precise machining solutions. Small CNC lathes, specifically, offer an ideal blend of compactness and versatility, making them essential tools for both hobbyists and professionals aiming to enhance their production capabilities.

The advantages of employing a small CNC lathe are manifold. Their ability to produce intricate components with high repeatability allows for greater creativity and efficiency in design. As noted in a study by IBISWorld, the rise of customized manufacturing has led to a 7% increase in the use of CNC technology across various industries, from automotive to aerospace. This trend emphasizes the importance of mastering the operational techniques of small CNC lathes, as they become indispensable in meeting the demands for precision and quality.

Equipping oneself with the right skills and knowledge to operate a small CNC lathe not only streamlines the machining process but also significantly enhances the end product. Whether constructing prototypes or producing small batches, understanding the capabilities and best practices associated with small CNC lathes is imperative for success in today's competitive landscape. By tapping into the potential of these machines, makers and manufacturers can achieve unparalleled quality and precision in their projects.

Understanding the Basics of Small CNC Lathes and Their Applications

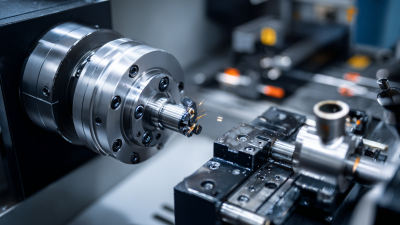

When embarking on a project that demands precision engineering, small CNC lathes have proven to be invaluable tools. Understanding the basics of these machines begins with their ability to automate turning processes, allowing for intricate designs that would be nearly impossible to achieve by hand. Small CNC lathes work by utilizing computer-controlled movements to precisely shape various materials, such as metal or plastic, into the desired forms. This level of automation not only speeds up production but also ensures high consistency across multiple parts.

The applications of small CNC lathes are vast, ranging from crafting custom prototypes to producing small-scale production runs. They are particularly popular in industries such as manufacturing, prototyping, and even hobbyist craftsmanship. By integrating sophisticated features like programmable settings and real-time monitoring, users can create detailed components with minimal waste. As more people explore the capabilities of these machines, understanding their fundamentals becomes essential for achieving outstanding results in both professional and personal projects.

Choosing the Right Small CNC Lathe for Your Project Needs

When embarking on a new project, selecting the right small CNC lathe is crucial to achieving the desired precision and efficiency. According to a report by the Association for Manufacturing Technology (AMT), small CNC machines have seen a surge in adoption, with a 15% increase in sales in the last year alone. This growth highlights the industry's shift towards more compact and versatile machinery, allowing artisans and small manufacturers to execute intricate designs with minimal waste.

When choosing a small CNC lathe, it's essential to consider factors such as size, accuracy, and advanced features. A study from the International Journal of Advanced Manufacturing Technology indicates that precision lathes can achieve tolerances as tight as ±0.001 inches, making them ideal for projects requiring high detail, such as jewelry or intricate components for electronics. Additionally, modern small CNC lathes offer user-friendly interfaces and software integrations that streamline the programming process, reducing setup times and increasing productivity—an essential factor as the demand for customized solutions continues to rise in various sectors.

Mastering Precision with Small CNC Lathes

This chart illustrates the precision capabilities of various small CNC lathes based on their spindle speed (RPM) and maximum turning diameter (mm). The data reflects the typical specifications of small CNC lathes used in various projects.

Essential Tools and Accessories for Small CNC Lathe Mastery

When it comes to mastering small CNC lathes, the right tools and accessories are essential for achieving precision in your projects. A reliable set of cutting tools, tailored for your specific materials, can make all the difference in ensuring smooth cuts and high-quality finishes. Invest in high-speed steel (HSS) or carbide tools, as these materials provide durability and sharper edges for intricate designs. Moreover, having a good selection of tool holders can greatly enhance your machining capabilities by allowing quick changes and adjustments.

Tips: Always keep your cutting tools sharp; dull tools can lead to poor finishes and increase the risk of damaging your workpiece. Regularly inspect your tools for wear and replace them as necessary to maintain precision.

Another crucial accessory to consider is a quality chuck. A well-fitted chuck will secure your workpiece firmly, preventing any movement during the turning process. Additionally, incorporating a digital readout (DRO) system can improve measurement accuracy, making it easier to replicate dimensions across multiple projects.

Tips: When selecting a chuck, prioritize compatibility with your lathe and the types of projects you plan to undertake. A DRO system can seem like an investment at first, but the time saved on precise measurements will pay off in the long run.

Step-by-Step Guide to Setting Up Your Small CNC Lathe

Setting up your small CNC lathe is a crucial step in achieving precision for your next project. Begin by selecting an appropriate location that is both spacious and well-ventilated. Ensure that the lathe is placed on a sturdy, level surface to minimize vibrations that could affect accuracy during operation. Connecting the lathe to a reliable power source is essential, as is checking for compatibility with your control software. Make sure all safety protocols are in place, wearing protective gear and keeping the workspace organized to prevent accidents.

Next, calibrate your lathe by following the manufacturer's instructions. This typically involves aligning the spindle and tailstock, setting up the tool post, and configuring the cutting tools. Use high-quality materials for your initial test runs to help refine your settings. Don’t forget to double-check your measurements when loading materials to ensure they are securely fastened. Finally, run a few trial projects, adjusting the parameters as needed to perfect your technique and achieve the desired results. This meticulous approach to setup will lead to enhanced precision and efficiency in your CNC turning tasks.

Mastering Precision with Small CNC Lathes for Your Next Project

| Feature | Details |

|---|---|

| Machine Type | Small CNC Lathe |

| Max Diameter | 5 inches |

| Max Length | 10 inches |

| Control Type | G-code |

| Spindle Speed | 2500 RPM |

| Power Requirement | 220V, 1 Phase |

| Weight | 150 lbs |

| Software Compatibility | CAD/CAM Software |

Tips for Optimizing Precision and Quality in CNC Machining Projects

When embarking on a CNC machining project, achieving optimal precision is paramount. Small CNC lathes, often praised for their compact size and agility, can be leveraged to enhance the detailing of your projects. One key tip for maximizing precision is to ensure that your machine is properly calibrated. Regular checks on the machine's alignment and settings can prevent errors that might arise from miscalculations, ensuring that each cut is as precise as possible.

Another critical factor in optimizing quality is the selection of appropriate tooling. Using high-quality cutting tools specifically designed for your material can significantly improve the finish of the workpiece. Furthermore, incorporating advanced tooling techniques, such as multi-point cutting, can yield finer results. It's also beneficial to maintain a clean workspace, as debris can easily lead to inaccuracies during machining. By focusing on these crucial aspects, you can elevate the precision and quality of your CNC projects, resulting in superior outcomes that meet your project's demands.

Related Posts

-

Setting the Gold Standard: Industry Production Guidelines for the Best CNC Lathes

-

The Ultimate CNC Lathe Buying Guide: Key Factors for Global Procurement Success

-

Global Sourcing Chinese Excellence: Why the Best CNC Lathe Machines Dominate World Markets

-

Unlocking the Power of CNC Turning Tips for Global Buyers in the Digital Era

-

Shaping the Future of CNC Machines at the 138th Canton Fair in 2025

-

Unlocking the Potential of CNC Turning for Precision Manufacturing Success

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska