Ultimate Guide to Mastering Your First Desktop CNC Mill for Precision Engineering

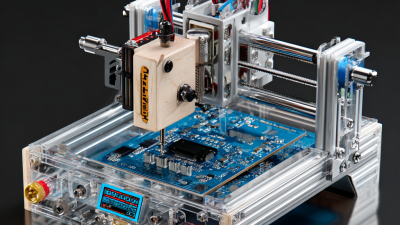

In the ever-evolving world of precision engineering, mastering your first desktop CNC mill can be a game-changer for both hobbyists and professionals alike. This ultimate guide is designed to provide you with essential insights and practical tips for navigating the intricacies of desktop CNC milling. From understanding the fundamental components and software to optimizing settings for precision cuts, we will cover everything needed to elevate your craftsmanship. Whether you are venturing into the world of CNC for the first time or looking to refine your existing skills, our comprehensive approach ensures that you will gain the confidence to harness the full potential of your desktop CNC mill. Join us as we delve into the best practices, tools, and tricks that will empower you to create high-quality projects with accuracy and finesse.

Choosing the Right CNC Mill: Key Considerations for Beginners

Choosing the right CNC mill is crucial for beginners aiming to achieve precision in their engineering projects. First, consider the size of the mill. A desktop CNC mill is a great choice for small workshops, but you must ensure it can handle the materials and projects you intend to work on. Opting for a model with a versatile work area can help you accommodate various projects as your skills develop.

When selecting a CNC mill, pay close attention to the spindle power and speed. A mill with a powerful spindle can cut through tougher materials more efficiently, while adjustable speeds allow for more precision control in different tasks. Beginners might find it helpful to choose a machine with a user-friendly interface, making it easier to learn the control software.

**Tips:** Research user reviews for insights on reliability and ease of use. Additionally, consider CNC mills that come with robust support communities; this can be invaluable for troubleshooting and learning. Lastly, ensure that any model you choose allows for easy upgrades, so your mill can grow with your skills as you advance in precision engineering.

Key Factors Influencing CNC Mill Selection for Beginners

Essential Software for Your CNC Mill: A Comprehensive Overview

When stepping into the world of CNC milling, having the right software is essential for maximizing the precision and efficiency of your projects. There are several types of software crucial for operating a desktop CNC mill, each serving a unique purpose that enhances the machining process. CAD (Computer-Aided Design) software allows users to create intricate designs and technical drawings, ensuring that every dimension is accurate before transitioning to the production phase. Popular choices like Fusion 360 and SolidWorks provide robust tools for 3D modeling, making them ideal for both beginners and experienced engineers.

Once the design is complete, the next step is to use CAM (Computer-Aided Manufacturing) software to generate toolpaths. CAM software takes the CAD files and translates them into machine code that the CNC mill can understand. This is where precision engineering truly comes to life, as the software factors in various parameters such as feed rates and spindle speeds to create an effective machining plan. Programs like Mach3 and EstlCAM have gained popularity for their user-friendly interfaces, enabling users to optimize their milling operations quickly. By understanding and effectively utilizing these essential software tools, users can enhance their CNC milling experience and achieve superior results in their engineering projects.

Ultimate Guide to Mastering Your First Desktop CNC Mill for Precision Engineering

| Software Name | Description | Operating System | Price Range | User Level |

|---|---|---|---|---|

| Fusion 360 | A powerful CAD/CAM tool for designing, engineering, and manufacturing. | Windows, macOS | Free - $495/year | Beginner to Advanced |

| Mach3 | A popular control software for CNC milling machines. | Windows | $200 - $300 | Intermediate |

| Estlcam | Software for creating G-code for CNC machining and engraving. | Windows | $60 | Beginner |

| GRBL | An open-source firmware for controlling CNC machines. | Cross-platform | Free | Beginner to Intermediate |

| SolidWorks | A 3D CAD software used for modeling and simulations. | Windows | $3995 - $7995 | Advanced |

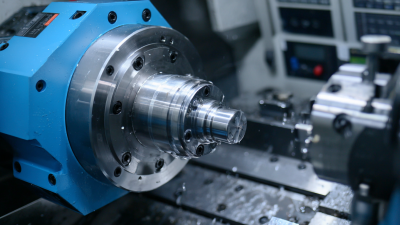

Setting Up Your CNC Mill: Step-by-Step Guide for Precision Alignment

Setting up your CNC mill is a critical first step towards achieving precision in engineering projects. Proper alignment not only ensures that cuts are accurate but also extends the life of your tools. A notable report by the National Institute of Standards and Technology (NIST) highlights that misalignment can lead to errors as much as 0.005 inches, which can significantly impact the quality of machined components in precision engineering. Thus, careful calibration of your CNC setup is essential for mitigating costly mistakes and enhancing overall productivity.

One effective method for ensuring precision alignment is using a dial indicator. According to industry standards, using this tool allows for measurements with an accuracy of up to 0.0001 inches. When setting up your CNC mill, it’s advisable to perform iterative tests, adjusting the position of the mill as needed until the readings are consistent. This method not only emphasizes the importance of quality control but also adheres to best practices as outlined in engineering guides, which report that proper setup can increase throughput by up to 20%. By focusing on meticulous alignment processes, operators can maximize efficiency and ensure that their CNC machining meets the demands of high-precision applications.

Top Tips for Maintenance: Ensuring Longevity of Your CNC Equipment

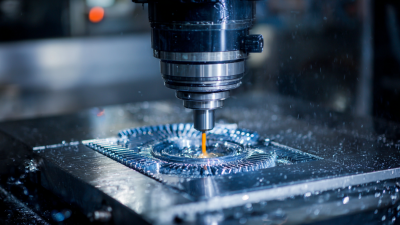

When it comes to maximizing the performance and longevity of your CNC mill, regular maintenance is key. High-quality CNC equipment is an investment, and like any precise machinery, it requires proper care to avoid costly breakdowns. One critical aspect of maintenance is ensuring that the spindle is frequently inspected and serviced. It's a common misconception that all spindle rebuilds are equal—understanding the specific requirements and issues of your machine can significantly impact its functionality in applications ranging from milling to cutting.

Another important tip for maintaining your CNC equipment is to prioritize the use of appropriate cutting tools and materials. For instance, machines with adequate horsepower and torque are essential, especially when working with tough materials like stainless steel. Using the right tools not only enhances the quality of your work but also reduces wear and tear on the machine, contributing to its overall longevity.

Additionally, keeping up with new technology and innovations in manufacturing can lead to significant improvements in your CNC operations. Implementing modern engineering techniques can optimize performance and efficiency, ensuring that your setup remains competitive and functional for years to come. Regularly updating your knowledge and tools will help you maintain a high standard in precision engineering.

Common Mistakes to Avoid: Lessons Learned from First-Time CNC Users

When venturing into the world of CNC milling, first-time users often overlook critical aspects that can lead to frustrating experiences. According to a survey by the Association for Manufacturing Technology, nearly 48% of new CNC users reported issues stemming from improper setup or calibration. This highlights the importance of thoroughly understanding the machine’s specifications and following the manufacturer’s instructions to achieve optimum precision. Failing to adequately calibrate the CNC mill can result in inaccurate cuts, wasted materials, and costly rework.

Additionally, many newcomers tend to underestimate the importance of tool selection and maintenance. A report from the National Institute of Standards and Technology indicates that tool wear can account for up to 30% of manufacturing downtime in CNC machining. Using inappropriate tools or neglecting regular maintenance not only hampers the quality of work but can also lead to permanent damage to the machinery. By investing time in learning about the right tooling options and ensuring regular checks, users can enhance productivity and extend the lifespan of their equipment significantly.

Related Posts

-

The Future of Precision Engineering: Revolutionizing Manufacturing with the Best Desktop CNC Mills

-

Discovering Quality Suppliers for the Best Mini CNC Machine in a Competitive Market

-

Exploring the Future of Best Milling Machines in 2025 Industry Trends and Innovations

-

Exploring Unique Features and Applications of Best CNC Manufacturing Solutions

-

20 Best Features of the Best CNC Wood Cutting Machine

-

Unlocking Efficiency and Precision with Best CNC Manufacturing Solutions

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska