Innovative Insights into Mini CNC Machine Technology Trends Shaping 2025 Global Manufacturing

As we approach 2025, the landscape of global manufacturing is undergoing a radical transformation, driven by advancements in technology and an increasing demand for precision and efficiency. Among the pivotal innovations, the mini CNC machine is revolutionizing the industry, offering a compact solution that marries performance with versatility. According to a recent report by MarketsandMarkets, the CNC machine market is projected to reach USD 100 billion by 2025, with mini CNC machines accounting for a significant share due to their cost-effectiveness and adaptability for small-scale production and prototyping. China's commitment to high-quality manufacturing positions it as a crucial player, as it embraces these trends to meet the evolving needs of global partners. By harnessing the capabilities of mini CNC machines, manufacturers can enhance productivity, streamline operations, and maintain a competitive edge in an increasingly dynamic market.

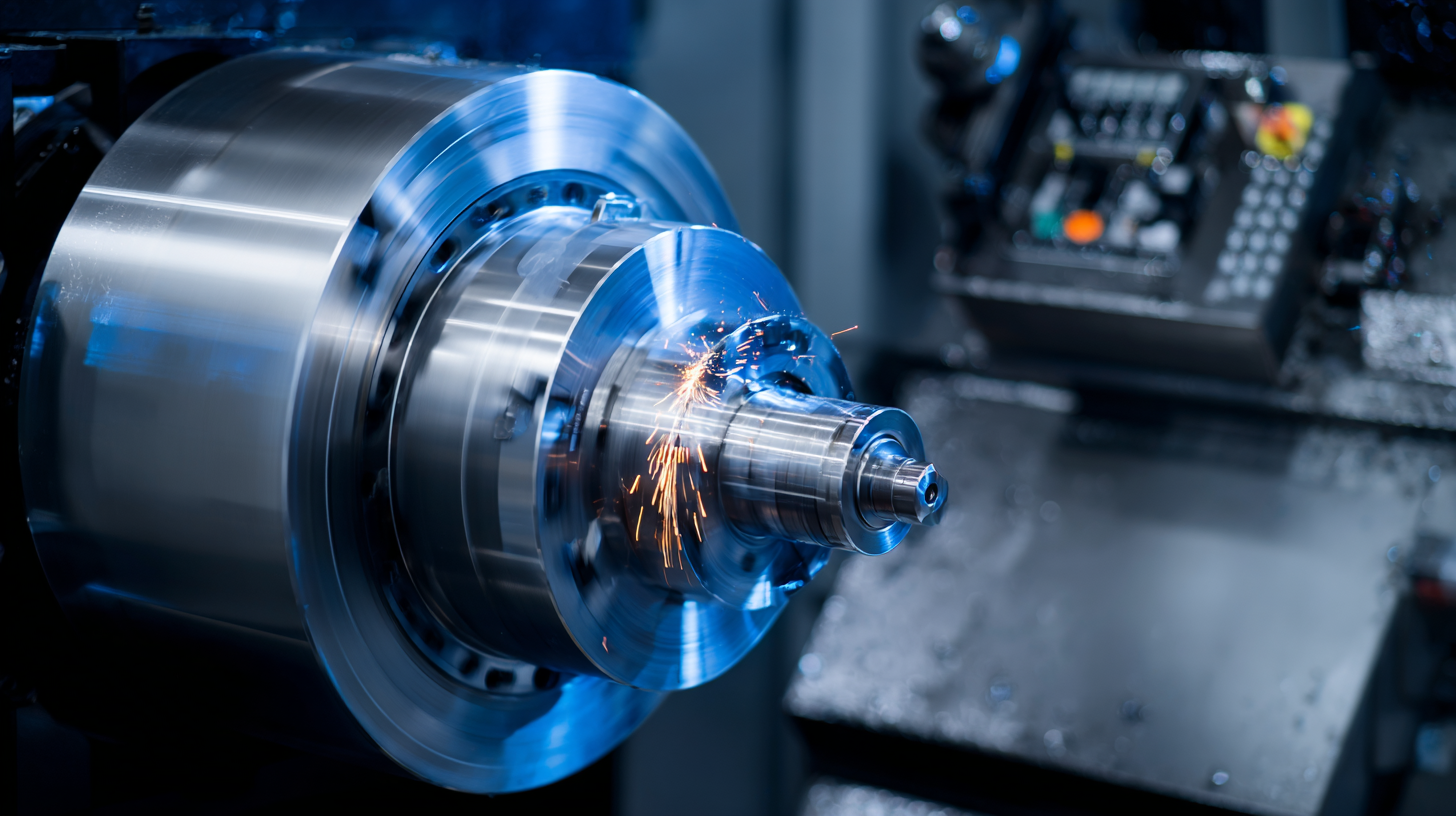

Emerging Mini CNC Technologies Transforming Precision Engineering in 2025

As we look toward 2025, the landscape of precision engineering is set to undergo a radical transformation driven by emerging mini CNC technologies. New advancements, including enhanced software algorithms and high-speed machining capabilities, are enabling manufacturers to achieve unparalleled precision and efficiency. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $117 billion by 2025, with mini CNC machines emerging as a driving force in this growth due to their compact size and versatility.

One of the more notable trends is the integration of AI and IoT into mini CNC systems, facilitating real-time data analytics and predictive maintenance. This not only reduces downtime but also optimizes production processes. The 2021 Global Industry Analysts report highlighted that intelligent automation in manufacturing could boost productivity by up to 30%. As mini CNC machines continue to evolve, their capabilities for intricate design and fabrication will revolutionize sectors such as aerospace, automotive, and medical device manufacturing, establishing a new benchmark for precision engineering.

Impact of Advanced Materials on Mini CNC Machine Performance and Durability

The evolution of mini CNC machine technology is significantly influenced by the adoption of advanced materials, which enhance both performance and durability. As per the latest report from ResearchAndMarkets, the global CNC machine market is projected to reach $100 billion by 2025, with mini CNC machines comprising a substantial portion of this growth. Advanced materials, such as carbon fiber composites and high-strength aluminum alloys, are transforming the capabilities of these compact machines, allowing for greater precision and efficiency in manufacturing processes.

Incorporating advanced materials not only improves the structural integrity of mini CNC machines but also extends their lifespan. A study by Deloitte reveals that machines utilizing lighter and stronger materials can achieve a performance increase of up to 30%, significantly reducing wear and tear. Additionally, innovations like ceramic-based coatings are being employed to further enhance durability against abrasion and thermal fatigue, making mini CNC machines more reliable in high-demand environments. As manufacturers increasingly prioritize efficiency and sustainability, the synergy between advanced materials and mini CNC technology will undoubtedly play a critical role in shaping the future of global manufacturing.

Integration of AI and Automation: Shaping the Future of Mini CNC Operations

The integration of artificial intelligence (AI) and automation is revolutionizing the landscape of mini CNC machine operations, ushering in a new era of precision manufacturing. As industries pursue more efficient production methods, AI's ability to analyze vast amounts of data in real-time empowers mini CNC machines to optimize their operational parameters. For instance, predictive maintenance powered by AI can foresee potential machine failures, allowing enterprises to minimize downtime and enhance productivity rates.

Moreover, automation technologies are streamlining the workflow processes within mini CNC operations. With robotic arms and advanced software working in tandem, tasks that once consumed significant labor hours can now be executed swiftly and consistently. This not only reduces the risk of human error but also enables smaller manufacturers to scale up their production without a proportional increase in costs. As we look towards 2025, the synergy between AI and automation will be pivotal in shaping a more agile and responsive manufacturing environment, driving innovation and competitiveness across the globe.

Sustainability Trends Driving the Design of Mini CNC Machines

As the manufacturing landscape evolves, sustainability is taking center stage in the design and development of mini CNC machines. These compact machines are not only transforming productivity but are also adhering to green principles, making them an attractive solution for environmentally conscious manufacturers. Engineers and designers are increasingly focusing on materials that reduce waste and energy consumption, such as biodegradable plastics and lightweight alloys. This shift not only minimizes the ecological footprint but also enhances the efficiency of operations, paving the way for a more sustainable manufacturing era.

Moreover, advancements in technology are allowing mini CNC machines to incorporate smart features that optimize resource use. For instance, integrated sensors and IoT capabilities enable real-time monitoring of energy consumption, allowing manufacturers to make data-driven decisions that further reduce waste. Automated systems designed for recycling off-cuts and leftover materials are also becoming increasingly popular, ensuring that every piece generated in the machining process is utilized efficiently. By embracing these sustainability trends, mini CNC machines are positioned not just as tools for production, but as vital components in the quest for a greener future in global manufacturing.

Trends in Mini CNC Machine Technology Influencing Global Manufacturing (2025)

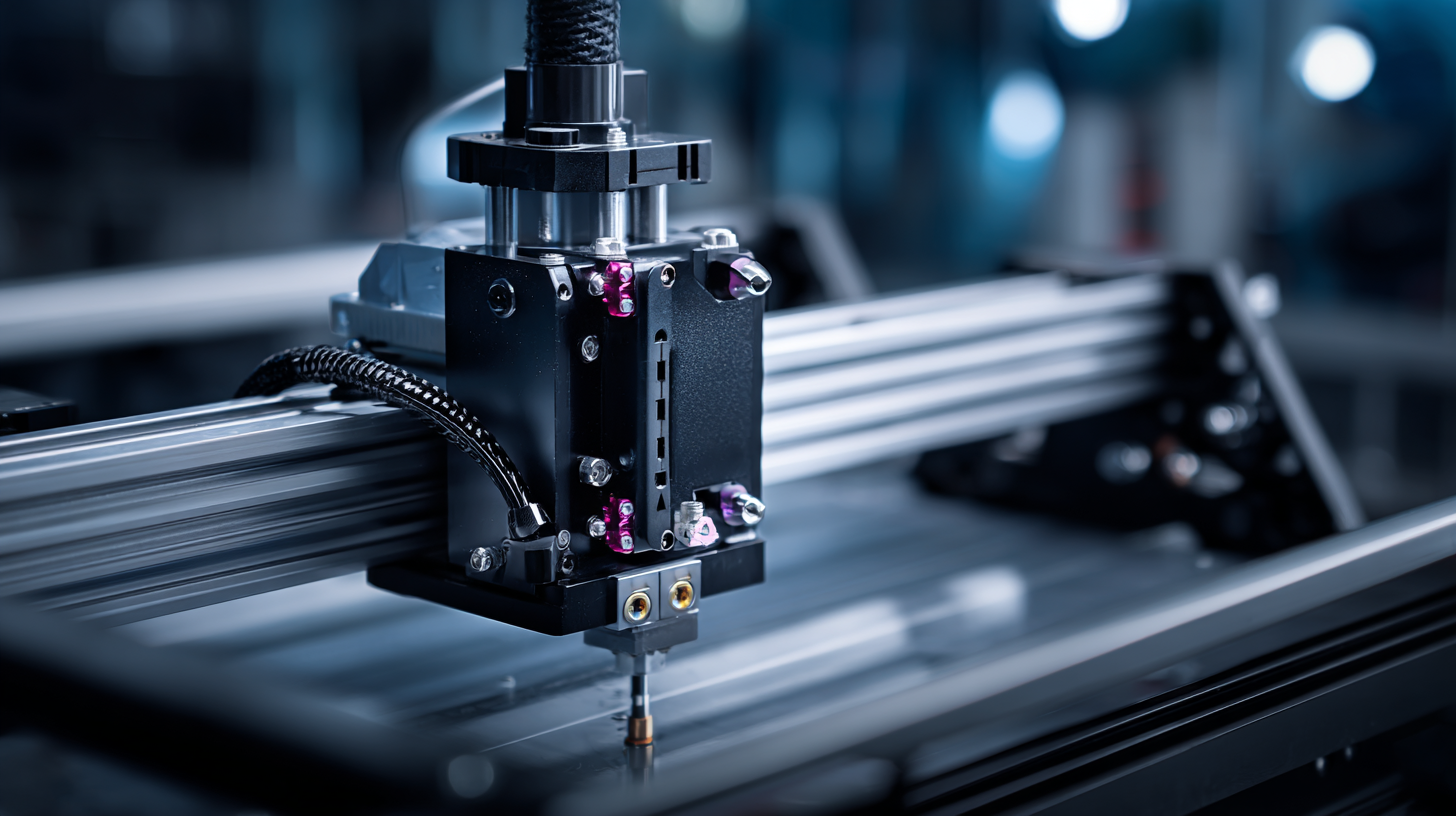

The Rise of User-Friendly Interfaces in Mini CNC Technology for Widespread Adoption

The rise of user-friendly interfaces in mini CNC technology is transforming the landscape of global manufacturing, making advanced machining techniques more accessible than ever before. As manufacturers strive for efficiency and innovation, the integration of intuitive Human Machine Interfaces (HMI) is becoming a pivotal factor in widespread adoption. This shift is not only enhancing operational efficiency but also driving a surge in productivity across various industries, particularly in woodworking and complex component fabrication.

With the global woodworking machinery market projected to grow significantly, reaching $7.88 billion by 2032, the demand for advanced yet user-friendly mini CNC machines is expected to rise correspondingly. The increasing complexity of modern manufacturing processes necessitates systems that allow operators to quickly adapt and produce high-quality outcomes. As HMI technology evolves, it becomes a critical asset, streamlining the interaction between users and machines, thereby reducing the learning curve and promoting a smoother workflow. Companies are now investing in these technologies, recognizing the potential for improved precision and reduced operational errors, which ultimately translates to faster production timelines and better product quality.

Innovative Insights into Mini CNC Machine Technology Trends Shaping 2025 Global Manufacturing

| Dimension | Current Trend | Future Projection (2025) | Impact on Adoption |

|---|---|---|---|

| User-Friendly Interfaces | Increased development of graphical user interfaces (GUIs) | Widespread adoption across non-expert users | Enhances accessibility and reduces learning curve |

| Automation Integration | Rise of automated workflows in CNC operations | Increased efficiencies and reduced operation time | Promotes higher production rates and productivity |

| Material Versatility | Growing use of diverse materials in mini CNC machining | Expansion into advanced composite materials | Enables broader application range in industries |

| Portability | Emergence of compact and mobile CNC machines | High demand for portable manufacturing solutions | Opens up opportunities for on-site fabrication |

| Cost Efficiency | Decreasing costs of mini CNC machines | More budget-friendly options available | Encourages small businesses to adopt technology |

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska