How to Optimize CNC Milling for Enhanced Precision and Efficiency

CNC milling has emerged as a cornerstone of modern manufacturing, driving innovation and enhancing production capabilities across various industries. According to a report by MarketsandMarkets, the CNC machining market is expected to reach $117.12 billion by 2026, reflecting a compound annual growth rate (CAGR) of 7.3% from 2021. This growth underscores the increasing reliance on CNC milling for precision machining that meets stringent tolerances and efficiency standards. As manufacturers strive to improve productivity and reduce operational costs, optimizing CNC milling processes becomes imperative. By implementing advanced strategies and technologies, companies can not only enhance precision but also streamline workflows, ultimately delivering high-quality products while maximizing resource utilization. This blog will explore effective techniques and best practices for optimizing CNC milling, ensuring that manufacturers remain competitive in a rapidly evolving market.

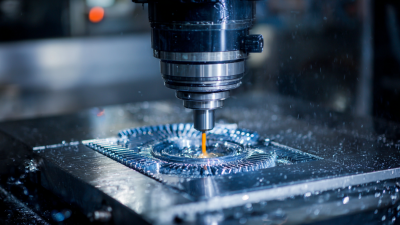

Understanding the Fundamentals of CNC Milling and Its Industrial Applications

CNC milling is a critical process in modern manufacturing, enabling the precise shaping of materials ranging from metals to plastics. Understanding the fundamentals of CNC milling is essential for optimizing performance and achieving superior results. The process involves the use of computer-controlled machines that can create intricate designs with high accuracy. This technology is widely employed in various industries, including aerospace, automotive, and medical, where precision engineering is paramount.

To enhance efficiency and precision in CNC milling, consider implementing the following tips. First, always ensure that your tooling is appropriate for the material being machined; using the right tools can significantly reduce wear and improve the quality of the finished product. Second, regular maintenance of your CNC machine is crucial. Keeping the machine in optimal condition helps prevent downtime and ensures consistent performance. Lastly, optimizing cutting parameters, such as feed rates and spindle speeds, can significantly impact both the quality of the milling operation and overall cycle times.

By grasping the fundamentals of CNC milling and applying these tips diligently, manufacturers can achieve better precision and efficiency, ultimately leading to improved production outcomes.

Key Factors Influencing Precision in CNC Milling Processes

Precision in CNC milling processes is influenced by several key factors that can significantly enhance both the quality of the final product and the efficiency of the manufacturing system. One primary determinant of precision is the machine's dynamic performance, including its rigidity and stability. According to a report from the International Journal of Advanced Manufacturing Technology, increasing machine rigidity by just 20% can improve precision by up to 30%, minimizing deviations during the cutting process.

Another critical factor is the tooling used in CNC milling. The choice of materials and coatings for cutting tools can greatly affect wear rates and surface finishes. A study by the Manufacturing Technologies Association found that using advanced carbide tools with a specialized coating can extend tool life by 50% while maintaining tight tolerances. Moreover, the optimization of cutting parameters—such as feed rate, speed, and depth of cut—plays a crucial role. Research indicates that a careful balance between these parameters can lead to a 40% increase in productivity while ensuring precision, making it essential for manufacturers to adopt a data-driven approach in parameter selection to achieve optimal results.

Advanced Tooling Solutions for Maximizing CNC Milling Efficiency

Advanced tooling solutions play a crucial role in maximizing CNC milling efficiency and precision. By selecting appropriate tools for specific materials and applications, manufacturers can significantly improve machining outcomes. Utilizing high-performance cutting tools designed for CNC milling can lead to smoother surfaces and reduced cycle times. Additionally, opting for coated tools can enhance tool lifespan and resistance to wear, ultimately minimizing downtime and maintenance costs.

To further optimize CNC milling processes, consider integrating toolpath optimization software. This technology analyzes and adjusts the cutting paths for ideal efficiency, ensuring that movements are minimized while maintaining precision. Operators should also regularly inspect and maintain their tooling systems, addressing any wear and tear promptly to preserve accuracy.

Another vital tip is to invest in automation and smart tooling solutions. Implementing adaptive tooling systems that can automatically adjust based on real-time feedback can elevate the machining process, providing consistent results and tightly controlled tolerances. Combining advanced tooling with smart technology not only enhances productivity but also enables manufacturers to stay competitive in the ever-evolving industry landscape.

Optimization of CNC Milling: Precision and Efficiency Metrics

Utilizing Software and Technology for Enhanced CNC Milling Accuracy

The CNC machining industry is poised for substantial growth, driven largely by advancements in software and technology that optimize milling processes for enhanced accuracy. As per recent market analysis, the global CNC machine market is projected to surge from $101.22 billion in 2025 to an impressive $195.59 billion by 2032, marking a compound annual growth rate (CAGR) of 9.9%. This rapid growth underscores the increasing reliance on computer numerical control technologies across various sectors, including aerospace, medical devices, electronics, and automotive, which demand highly precise components.

The integration of digital tools, such as digital twins and AI-driven algorithms, is revolutionizing manufacturing practices. These technologies not only streamline operations but also significantly boost the precision of CNC milling. With the onset of Industry 4.0, manufacturers are transitioning from mere automation to achieving autonomy, connectivity, and sustainability in their processes. The focus on optimizing CNC milling is further evidenced by initiatives like the digitization efforts undertaken by leading companies, aimed at enhancing operational efficiency and ultimately driving higher quality outputs in competitive markets.

How to Optimize CNC Milling for Enhanced Precision and Efficiency

| Parameter | Description | Optimal Value | Impact on Precision | Impact on Efficiency |

|---|---|---|---|---|

| Spindle Speed | The rotational speed of the spindle during milling | 12000 RPM | High | Moderate |

| Feed Rate | The speed at which the workpiece is fed into the milling cutter | 500 mm/min | Medium | High |

| Coolant Type | Type of coolant used during milling | Water-Soluble | Medium | Medium |

| Tool Material | Material from which the milling tool is made | Carbide | High | High |

| Workpiece Material | Material being processed | Aluminum Alloy | High | High |

The Role of Materials in Achieving Optimal CNC Milling Performance

When it comes to optimizing CNC milling for enhanced precision and efficiency, the choice of materials plays a crucial role. According to a report by the International Journal of Advanced Manufacturing Technology, nearly 30% of defects in machined components are attributed to inappropriate material selections. This highlights the importance of selecting materials that not only meet the mechanical requirements but also align with the CNC machine's capabilities. For instance, aluminum alloys like 6061-T6 are favored for their excellent machinability and lightweight properties, resulting in reduced cycle times and improved precision in milling operations.

Furthermore, material properties such as hardness and thermal conductivity significantly influence tool wear and machining speed. The Machining Research Group at MIT notes that using high-hardness materials without proper tool selection can lead to increased wear rates, ultimately negating the benefits of CNC technology. Conversely, materials like titanium and certain composites, while challenging to machine, can yield exceptionally durable components when milled with the appropriate tooling and strategies. By understanding and selecting the right materials, manufacturers can unlock the full potential of CNC milling processes, optimizing both precision and efficiency.

Related Posts

-

7 Innovative Best CNC Milling Techniques You Should Know About Today

-

Exploring Unique Features and Applications of Best CNC Manufacturing Solutions

-

Exploring Innovative Alternatives to CNC Milling Machines for Your Manufacturing Needs

-

Unlocking Precision: The Key Advantages of CNC Milling Machines for Modern Manufacturing

-

Unmatched Excellence in Best CNC Metal from Leading Chinese Manufacturers

-

The Future of Advanced CNC Machine Technologies in Global Manufacturing

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska