Discovering Quality Suppliers for the Best Mini CNC Machine in a Competitive Market

In the rapidly evolving landscape of manufacturing, the mini CNC machine has emerged as a game-changer, providing small businesses and individual craftsmen with precision machining capabilities previously reserved for larger enterprises. According to a recent report by MarketsandMarkets, the global CNC machining market is projected to grow from $63.1 billion in 2020 to $100.5 billion by 2025, underscoring the increasing demand for efficient and cost-effective machining solutions. As this competitive market expands, discovering quality suppliers becomes imperative for ensuring that businesses can leverage advanced mini CNC technology. By identifying reputable suppliers that offer reliable and innovative mini CNC machines, manufacturers can not only enhance their production capabilities but also achieve greater scalability in their operations. This blog will explore key strategies for finding the best suppliers in this dynamic market, helping you make informed decisions that drive success.

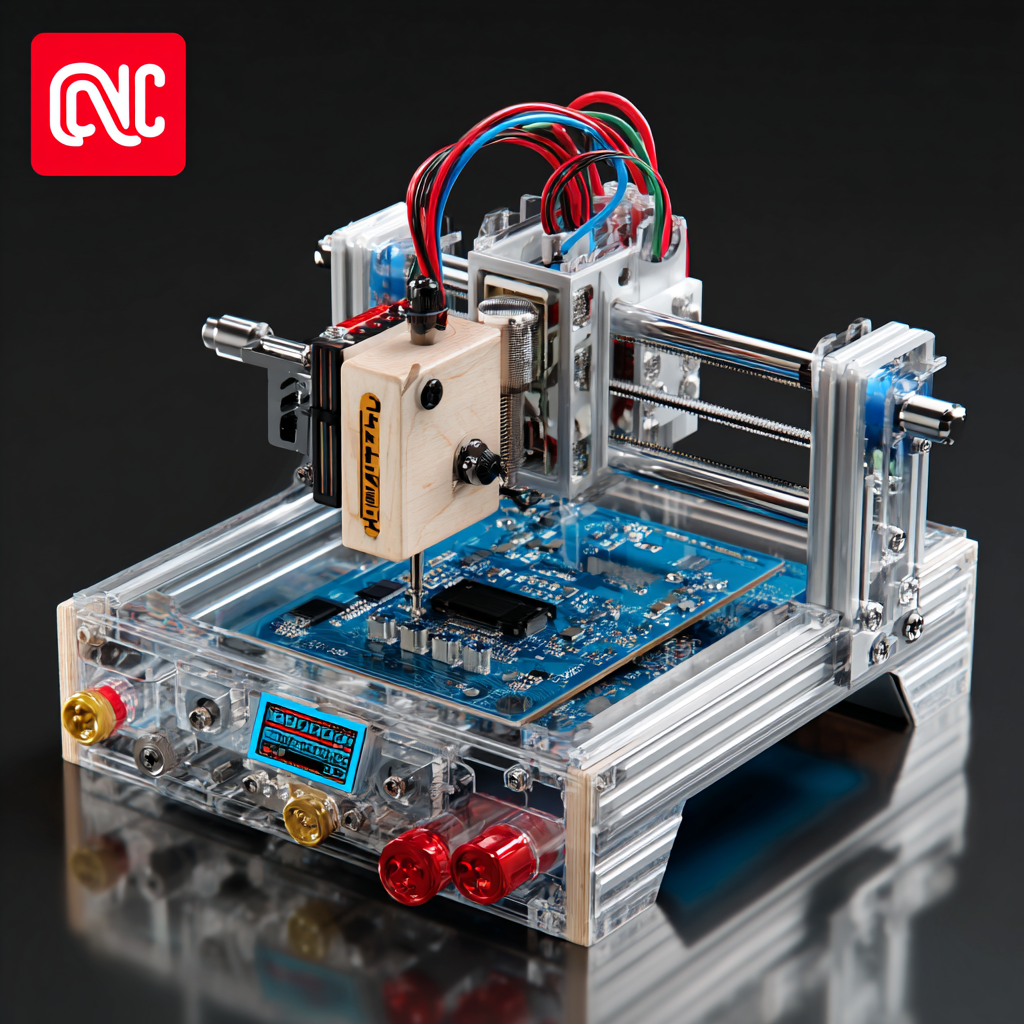

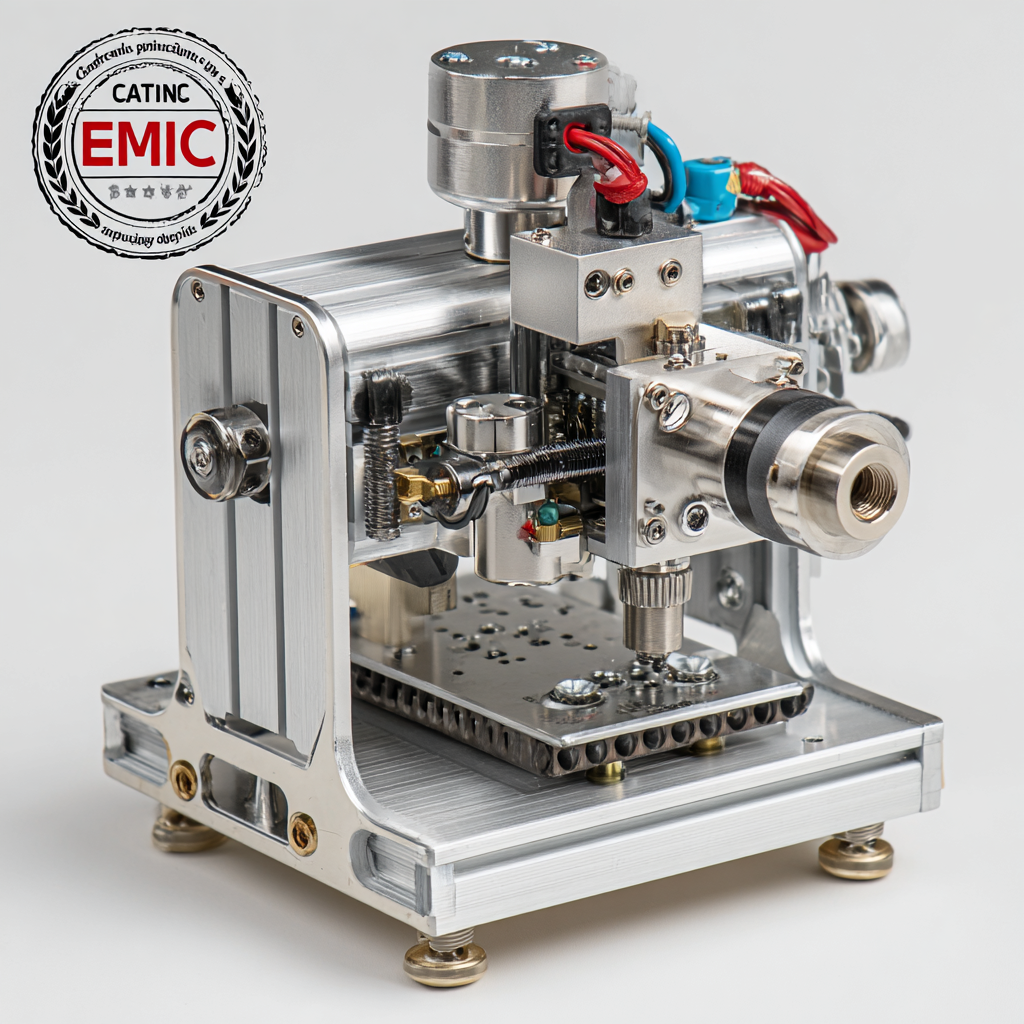

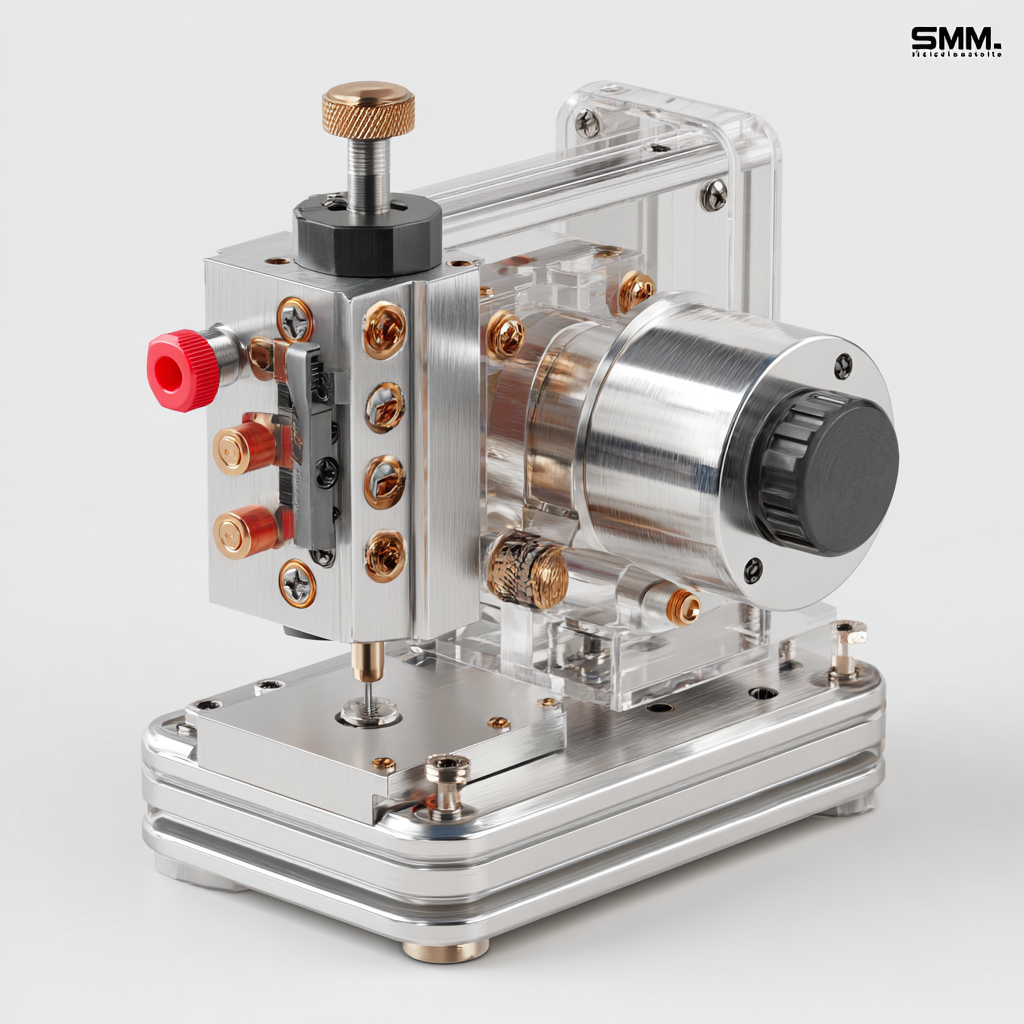

Identifying Key Features of High-Quality Mini CNC Machines

When searching for the best mini CNC machine, identifying key features that signify high quality is crucial. One of the most important aspects is the precision of the machining process. A high-quality mini CNC machine should provide consistent and accurate cuts, allowing users to produce intricate designs and prototypes with ease. This precision is often determined by the machine's motor capabilities, build quality, and the software it employs. Moreover, the availability of robust support and software tools can greatly enhance the user experience and operational efficiency.

Another critical feature to consider is the versatility of the machine. A well-designed mini CNC should be capable of handling various materials, from wood to plastics and even metals, offering users the flexibility they need to tackle different projects. Additionally, ease of use should not be overlooked; machines equipped with intuitive interfaces and comprehensive training resources can help novice users become proficient quickly. As the market becomes increasingly competitive, the demand for high-quality, reliable mini CNC machines continues to rise, making it essential for buyers to prioritize these features in their selection process.

Evaluating Supplier Credentials and Manufacturing Processes

In the competitive landscape of mini CNC machine manufacturing, evaluating supplier credentials and their manufacturing processes is crucial for companies seeking quality and reliability. As firms navigate the choice of suppliers, it becomes essential to assess not only their technological capabilities but also their track record and compliance with industry standards. This evaluation can include audits of manufacturing facilities, reviews of quality assurance practices, and understanding the innovation processes that underpin their operations.

Incorporating AI into supply chain management can enhance this evaluation process significantly. AI tools can analyze data on supplier performance, automate compliance checks, and predict potential disruptions, allowing companies to make informed decisions when selecting suppliers. Moreover, with tariffs reshaping trade dynamics, understanding how these policies impact supplier relationships and supply chain logistics becomes critical. By leveraging technology and focusing on sustainable practices, businesses can secure dependable suppliers that align with their goals of efficiency and environmental responsibility.

Understanding Market Trends in Mini CNC Machine Production

The mini CNC machine market is evolving rapidly, influenced by shifts in technology and consumer demands. Understanding these market trends is crucial for selecting quality suppliers. Manufacturers are increasingly focusing on producing machines that are not only compact and cost-effective but also packed with advanced features like automation and integration with software solutions. This adaptability ensures they meet the diverse needs of hobbyists and small businesses alike.

When searching for quality suppliers, consider a few key tips. Firstly, assess their reputation within the industry by seeking reviews and testimonials. Established suppliers often have a track record of reliability, which is essential for long-term partnerships. Secondly, prioritize suppliers who offer comprehensive customer support and training programs. This not only enhances user experience but also ensures you can maximize the machine's capabilities effectively.

Moreover, keep an eye on sustainability trends in production. Suppliers who prioritize eco-friendly manufacturing processes often provide transparency about their sourcing and production methods. This not only reflects their commitment to quality but also aligns with the values of environmentally conscious consumers. Matching these suppliers with your business needs can lead to a more fulfilling and competitive edge in the mini CNC machine market.

Comparing Pricing and Value Across Different Suppliers

In today's competitive market, discovering quality suppliers for mini CNC machines necessitates a thorough comparison of pricing and value. According to a recent study on consumer behavior, shoppers increasingly leverage price comparison tools to inform their purchasing decisions across a variety of sectors, including machinery. This trend underscores the importance of clear pricing structures and value assessments when selecting suppliers in the CNC market.

Research indicates that the evaluation of old versus new suppliers reveals significant differences in both pricing and the perceived value of services offered. A comparative analysis of supplier selection criteria shows that factors like reliability, cost efficiency, and product quality play pivotal roles. As manufacturers seek to optimize their supply chains, they must utilize data-driven insights to navigate the complexities of supplier comparisons effectively. By assessing these variables, businesses can capitalize on competitive pricing while ensuring they partner with suppliers that deliver high-quality products, ultimately enhancing their operational efficiencies.

Building Long-Term Relationships with Reliable Manufacturers

Building long-term relationships with reliable manufacturers is crucial when searching for the best mini CNC machine in a competitive market. Trust and communication form the foundation of these relationships, allowing both parties to collaborate effectively. Companies that prioritize transparency can create a culture of trust, encouraging manufacturers to invest in quality control and innovation. By sharing insights about production processes, timelines, and market demands, businesses can foster meaningful connections essential for growth.

**Tips for Building Strong Relationships:**

1. **Regular Communication:** Establish regular touchpoints with suppliers to discuss performance, challenges, and opportunities. This proactive approach ensures that all parties remain aligned and fosters a sense of partnership.

2. **Mutual Goals:** Identify and articulate shared objectives with your manufacturers. By collaborating on common goals, both parties can benefit and reinforce their commitment to the partnership.

3. **Feedback Loop:** Create a robust feedback mechanism that allows for open dialogue about products and services. This ensures that both you and your suppliers can adapt and improve continuously, leading to stronger relationships and ultimately better outcomes.

In today's competitive environment, nurturing these connections with manufacturers is not just a strategy; it's a vital element of business success. By following these tips, businesses can establish enduring partnerships that lead to long-term benefits in quality and service.

Discovering Quality Suppliers for the Best Mini CNC Machine in a Competitive Market - Building Long-Term Relationships with Reliable Manufacturers

| Supplier Location | Supplier Type | Product Range | Quality Certification | Average Lead Time | Pricing Model |

|---|---|---|---|---|---|

| USA | Manufacturer | Mini CNC Lathes, CNC Mills | ISO 9001 | 4-6 weeks | Tiered Pricing |

| Germany | Supplier | CNC Routers, Accessories | CE Mark | 3-5 weeks | Fixed Pricing |

| China | Distributor | Mini CNC Machines | ISO 9001 | 2-4 weeks | Volume Discounts |

| Japan | Manufacturer | CNC Milling Machines | JIS Certified | 5-7 weeks | Custom Pricing |

| Taiwan | Manufacturer | CNC Cutters, Rotary Tools | ISO 9001 | 4-6 weeks | Competitive Pricing |

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska