Discover Superior Manufacturing with the Best Desktop CNC Mill from Top Chinese Factories

In the modern landscape of manufacturing, the integration of advanced technology has revolutionized traditional processes, making precision and efficiency more accessible than ever before. Among these innovations, the desktop CNC mill stands out as a game-changer for both hobbyists and professionals alike. With the ability to transform digital designs into tangible products, these compact machines are gaining popularity for their affordability and versatility. This blog will explore the best desktop CNC mills sourced from top Chinese factories, highlighting their superior manufacturing capabilities and how they cater to a diverse range of applications.

As we delve into the features and benefits of these cutting-edge tools, you'll discover why investing in a desktop CNC mill could be the key to unlocking your creative potential while optimizing production workflows. Join us as we navigate through the best options available on the market today!

Exploring the Rise of Desktop CNC Mills in Chinese Manufacturing Industry

The rise of desktop CNC mills in the Chinese manufacturing industry marks a significant shift towards more decentralized and accessible production methods. According to a report by Research and Markets, the global CNC machining market is projected to reach $100 billion by 2025, with a substantial portion of this growth attributed to the increasing demand for precision-engineered components from small businesses and hobbyists. Desktop CNC mills, which are known for their compact size and affordability, are empowering a new wave of entrepreneurs in China to innovate and produce goods that were once limited to larger industrial machines.

Moreover, China's robust manufacturing ecosystem is fostering advancements in desktop CNC technology. With improvements in software and hardware, these machines are now capable of delivering high precision with minimal operational costs. A report from Statista indicates that the Chinese CNC machine tool market alone is expected to witness a compound annual growth rate (CAGR) of around 7% through 2023. This surge not only reflects the rising capabilities of desktop mills but also highlights the crucial role of Chinese manufacturers in leading the global CNC revolution. As production becomes more accessible, we can expect to see an explosion of creativity and innovation, particularly in sectors ranging from prototyping to custom parts fabrication.

Key Features to Look for in a Desktop CNC Mill from China

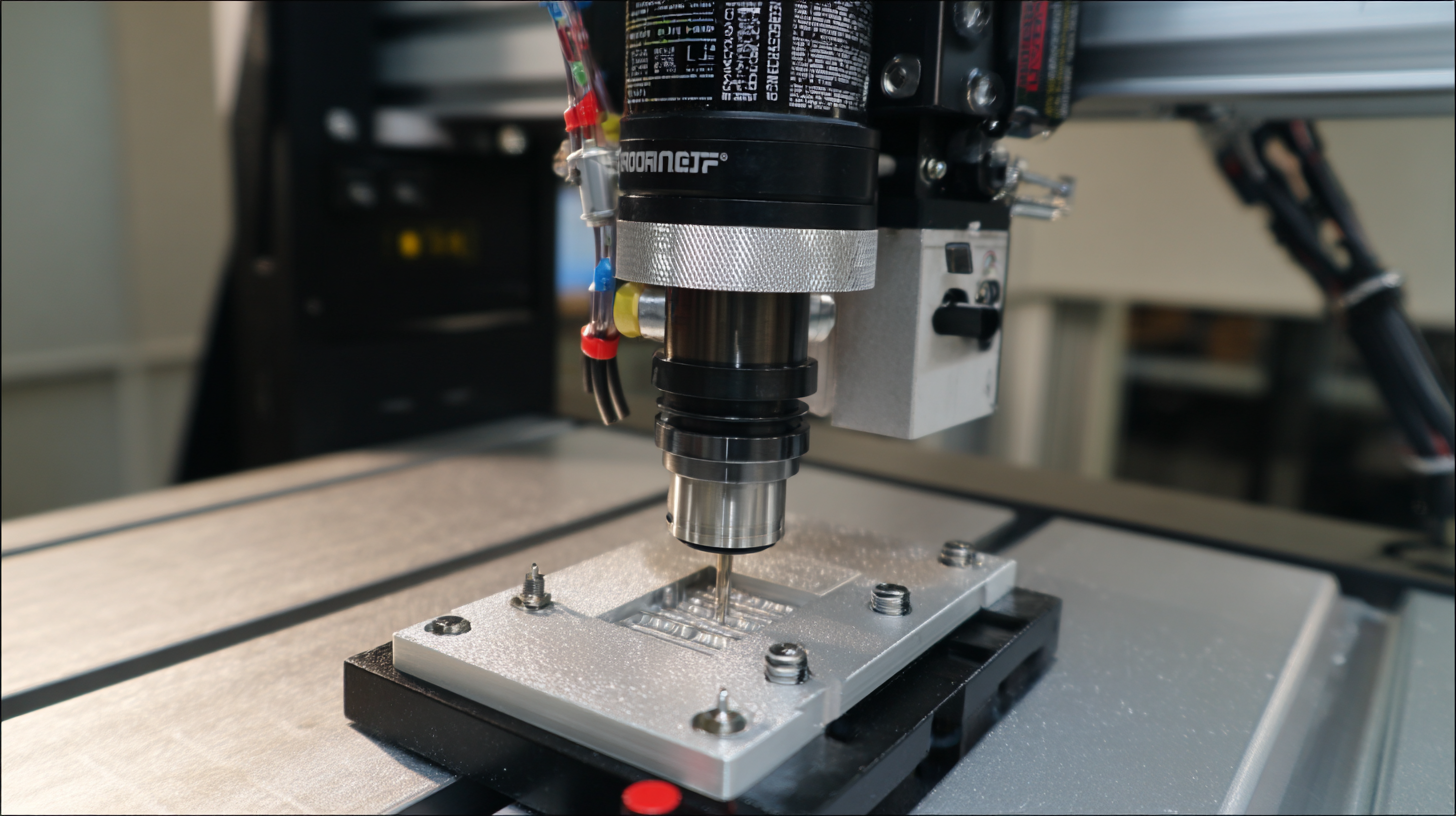

When selecting a desktop CNC mill from top Chinese factories, it's essential to understand the key features that can enhance your manufacturing experience. One crucial aspect is the machine's precision and accuracy. Look for models that offer high-resolution capabilities and robust build quality to ensure consistent performance. Additionally, consider the size and versatility of the machine to accommodate various projects, whether it's small intricate designs or larger components.

Another important factor is the software compatibility. A good desktop CNC mill should support popular software platforms, making it easier to streamline your workflow. For optimal results, consider models that come with user-friendly interfaces and have a proven track record with various design applications.

**Tips for Buyers:** When purchasing a CNC mill, check for customer reviews and testimonials to get insights into real-world performance. Additionally, ensure that the manufacturer provides adequate support and resources, including tutorials and manuals, to assist you in the learning curve. Lastly, evaluate the price-to-features ratio carefully; investing in a reliable machine can greatly enhance your productivity in the long run.

Comparative Analysis: Top Chinese CNC Mill Brands and Their Market Share

The CNC (Computer Numerical Control) machine market is experiencing robust growth, driven by increasing demand across various sectors. According to recent reports, the global market size for CNC machinery was valued at approximately USD 66.5 billion in 2020 and is projected to reach USD 130.1 billion by 2032, showing a significant compound annual growth rate (CAGR) of 5.6%. This surge is attributed to advancements in technology and the rising need for automation in manufacturing processes, making CNC machines a cornerstone of modern production.

In addition to the overall CNC market, the milling machine segment is also poised for substantial growth. The global milling machine market, which was valued at USD 13.22 billion in 2018, is expected to expand to USD 18.88 billion by 2032, achieving a CAGR of 2.4%. With China rapidly emerging as a key player in this domain, local manufacturers are not only enhancing their domestic production capabilities but are also improving innovation levels, catering to both local and global demands. This competitive landscape highlights the significance of understanding market shares among top Chinese CNC mill brands, which will further shape the industry dynamics in the coming years.

Cost Efficiency and Performance: How Chinese Desktop CNC Mills Stack Up

The rising prominence of desktop CNC mills manufactured in China is primarily attributed to their cost efficiency and robust performance. According to industry reports, the global CNC milling machine market is expected to reach approximately $100 billion by 2025, with the Asia Pacific region, led by China, playing a pivotal role in driving this growth. Chinese factories are leveraging advanced technology and streamlined manufacturing processes to produce desktop CNC mills that deliver precision machining at a fraction of the cost of their Western counterparts.

One of the key factors contributing to this cost efficiency is the scale of production. Chinese manufacturers benefit from economies of scale, allowing them to lower production costs without compromising quality. For instance, a recent study highlighted that Chinese CNC mills can operate at a 30% lower cost compared to similar machines produced in the US or Europe. This affordability has made them increasingly attractive for small businesses and hobbyists looking to invest in high-quality machining solutions.

**Tips:** When considering a desktop CNC mill from a Chinese factory, always check for certifications like ISO 9001 to ensure quality standards. Additionally, look for customer reviews and ratings to gauge the performance and reliability of the equipment. Lastly, exploring warranty options and after-sales support can further enhance the value of your investment, making sure you are well-covered if any issues arise.

Discover Superior Manufacturing with the Best Desktop CNC Mill from Top Chinese Factories - Cost Efficiency and Performance: How Chinese Desktop CNC Mills Stack Up

| Model | Max Working Area (mm) | Spindle Power (kW) | Max Speed (RPM) | Price (USD) | Cost Efficiency Ratio |

|---|---|---|---|---|---|

| Model A | 300 x 200 x 200 | 1.5 | 24000 | 1500 | 0.20 |

| Model B | 400 x 300 x 250 | 2.2 | 18000 | 2000 | 0.25 |

| Model C | 500 x 400 x 300 | 3.0 | 15000 | 2500 | 0.30 |

| Model D | 350 x 250 x 200 | 1.8 | 22000 | 1600 | 0.18 |

The Future of Desktop CNC Machining: Trends and Innovations from China

The landscape of desktop CNC machining is rapidly evolving, particularly with advancements emerging from China’s manufacturing sector. As technology continues to improve, we are witnessing a shift towards high-precision machines that not only enhance productivity but also are more user-friendly. Chinese manufacturers are at the forefront, innovating with features such as automatic tool changers, enhanced software integration, and real-time monitoring capabilities, making desktop CNC mills more accessible to hobbyists and professionals alike.

Moreover, sustainability has become a key trend within this industry. Many top factories in China are adopting eco-friendly materials and practices, ensuring that their manufacturing processes align with global sustainability goals. This commitment to reducing environmental impact alongside technological innovation is reshaping the desktop CNC market. The future looks promising, as these cutting-edge machines are set to democratize manufacturing, enabling anyone from DIY enthusiasts to small businesses to create complex parts efficiently and with minimal waste. As we navigate this new era, the influence of Chinese manufacturing will undoubtedly play a pivotal role in shaping the trajectories of desktop CNC machining worldwide.

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska