Exploring Unique Features and Applications of Best CNC Manufacturing Solutions

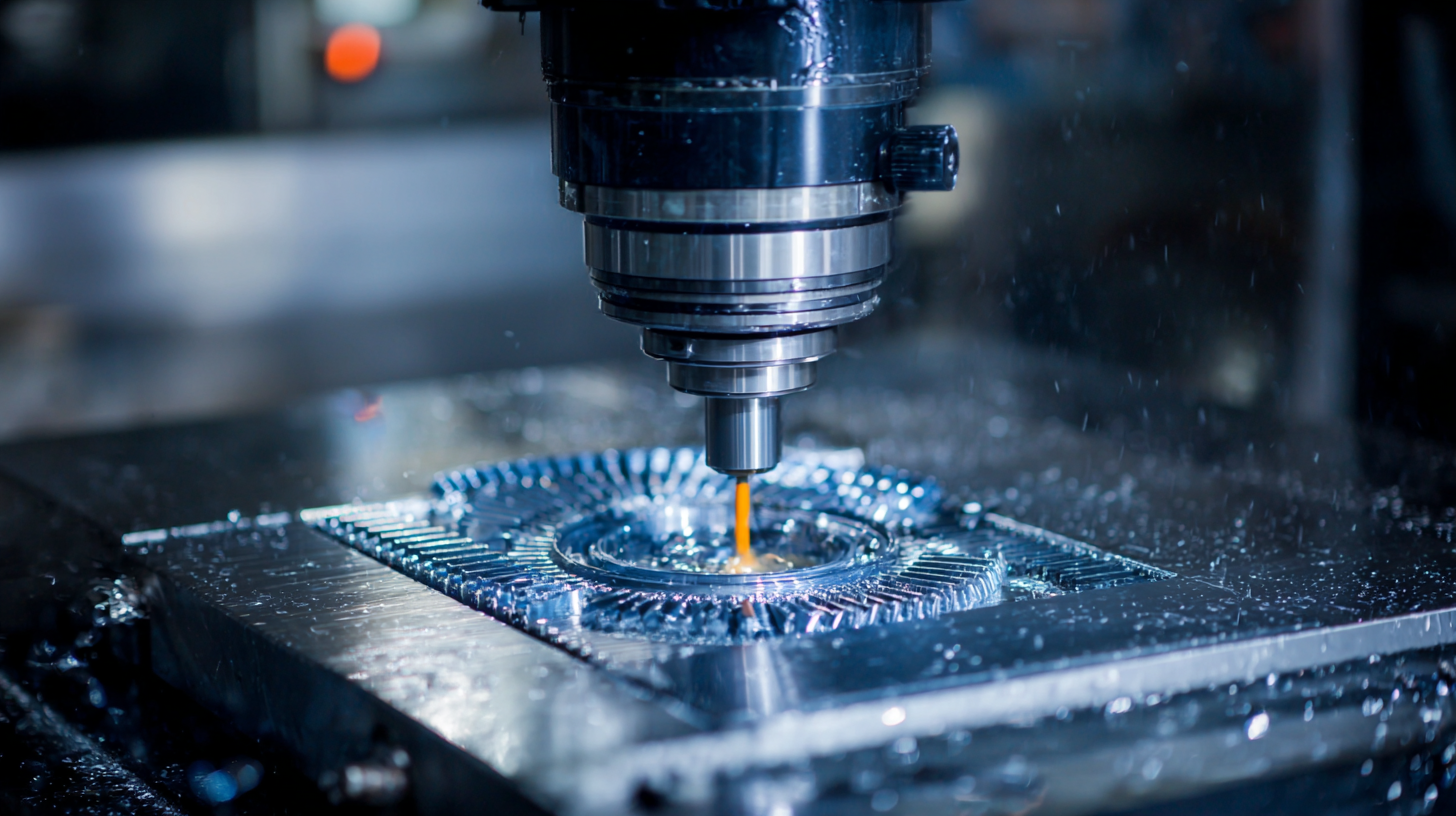

In today's rapidly evolving industrial landscape, CNC manufacturing stands out as a game changer, offering unparalleled precision and efficiency in production processes. As businesses strive to meet increasing demands for high-quality components, understanding how to select superior CNC manufacturing solutions becomes essential. This guide delves into the unique features and diverse applications of the best CNC manufacturing technologies available today. From intricate design capabilities to streamlined workflows, we'll explore the critical factors that define premium CNC manufacturers and how their offerings can significantly enhance operational performance.

Whether you're a seasoned engineer or a newcomer to the industry, equipping yourself with this knowledge will empower you to make informed decisions in your pursuit of top-tier CNC manufacturing solutions.

Understanding CNC Manufacturing: Key Statistics and Trends in 2023

CNC manufacturing continues to evolve, and understanding the key statistics and trends for 2023 reveals significant insights into this dynamic sector. As industries increasingly demand precision and efficiency, CNC technology is adapting to meet these needs. Current trends highlight a growing preference for automation and advanced software integration, which not only enhance production efficiency but also reduce operational costs. Moreover, the rise in demand for customized solutions indicates that businesses are looking for CNC systems that offer flexibility without compromising on quality.

In addition to traditional machining, the advent of additive manufacturing is reshaping the landscape. A recent executive survey of leading enterprises in the additive manufacturing sector identified several emerging trends that will define the future of production. Innovations in 3D printing technology, such as material advancements and faster production methods, are gaining traction and are likely to influence CNC machining processes. This synergy between CNC and 3D printing not only expands the capabilities of manufacturers but also opens up new applications across various industries, including aerospace, automotive, and healthcare. As we look forward to 2025, these developments will play a crucial role in how businesses approach manufacturing challenges and opportunities.

Exploring Unique Features and Applications of Best CNC Manufacturing Solutions

| Feature | Description | Application | Trend in 2023 |

|---|---|---|---|

| Automation | Integration of advanced robotics to enhance productivity and consistency. | High-volume manufacturing | Increasing adoption of automated systems to minimize human error. |

| 5-Axis Machining | Ability to cut parts from multiple angles for complex shapes. | Aerospace and automotive industries | Growing demand for intricate designs and lightweight components. |

| Cloud CNC | Remote operating capabilities for better job management. | Small to medium-sized enterprises | Increase in software solutions for remote access. |

| Material Versatility | Capability to work with various materials like metals, plastics, and composites. | Medical devices and tooling | Expansion into new material applications for diverse industries. |

| Real-time Monitoring | Sensors and software to track machine performance and maintenance needs. | All manufacturing sectors | Increase in predictive maintenance practices to reduce downtime. |

Innovative CNC Technologies: How They Transform Manufacturing Efficiency

CNC (Computer Numerical Control) technologies are revolutionizing the manufacturing sector, delivering unprecedented efficiency and precision. Recent studies indicate that implementing advanced CNC solutions can boost productivity by up to 30% while significantly reducing operational costs. For instance, a report by the International Federation of Robotics (IFR) states that manufacturers adopting automation technologies, including CNC machining, have experienced labor cost savings of approximately 25%. This shift in manufacturing practices is largely driven by the integration of innovative CNC systems, which incorporate real-time data analytics and machine learning algorithms to optimize production processes.

In addition to enhancing operational efficiency, these technologies are redefining the scope of manufacturing applications. A survey published by MarketsandMarkets highlights that the global CNC machining market is expected to reach $100 billion by 2026, growing at a CAGR of 6.8%. This growth is fueled by the adoption of CNC in various industries, including aerospace, automotive, and medical devices, where precision and accuracy are paramount. As manufacturers embrace these innovative CNC technologies, they are not only improving their efficiency but also ensuring quality and consistency in their output, thereby setting new standards in the industry.

Comparative Analysis of CNC Machining Types and Their Applications

CNC machining has evolved into various forms, each with its specific applications and advantages. A comparative analysis of CNC machining types reveals distinct functionalities tailored for diverse industrial needs. For instance, five-axis CNC machining is gaining significant traction due to its capability to perform complex geometrical tasks with high precision. As industry demands for accuracy escalate, the recent advancements in optimized dual NURBS curve interpolation strategies enhance the efficiency of path planning for these systems, proving critical in sectors where precision is paramount.

Furthermore, the growth of the CNC router machine market, projected to reach USD 691 million in 2023 with a CAGR of 3.5% from 2024 to 2030, underscores the increasing reliance on these technologies across industries. This expansion reflects the broader trend toward automation and precision in manufacturing, as industries seek sustainable practices. Within this context, the comparative analysis of production techniques, such as the exploration of microfluidic chip fabrication methods, highlights both applicability and limitations, driving innovation and efficiency in urgent diagnostics and micro-manufacturing applications.

Cost-Benefit Analysis: Investing in Advanced CNC Solutions for Businesses

In today's competitive manufacturing landscape, businesses are increasingly turning to advanced CNC solutions to enhance efficiency and production quality. A recent market report by Research and Markets indicates that the global CNC machine market is expected to reach $100 billion by 2026, growing at a compound annual growth rate (CAGR) of 6.5%. This growth emphasizes the importance of investing in CNC technologies, not just for their immediate impacts but also for long-term financial benefits.

When conducting a cost-benefit analysis, companies should consider not only the initial investment but also the potential savings generated through improved accuracy and reduced waste. Studies show that using CNC machines can decrease production time by up to 40%, leading to faster time-to-market and increased profitability. Additionally, automation and precision can reduce labor costs by as much as 25%, providing a significant return on investment over time.

**Tips:** When choosing a CNC solution, focus on scalability; options that can grow with your business will maximize your investment. Regularly analyze the performance of your CNC machines to identify areas for improvement, ensuring you continually enhance productivity and profitability. Lastly, factor in the long-term benefits of maintenance and support when assessing total cost of ownership.

Cost-Benefit Analysis of Advanced CNC Solutions

Future Trends: Predicting the Evolution of CNC Manufacturing Technologies

The future of CNC manufacturing is poised for dramatic transformation, prominently featuring the rise of 5-axis technology. This innovative development allows for unprecedented precision and versatility in machining operations, enabling manufacturers to produce complex geometries more efficiently. As industries increasingly demand superior quality with faster turnaround times, embracing multi-axis systems becomes crucial. This shift not only refines production capabilities but also signifies a growing trend toward automation and enhanced operational efficiency.

In conjunction with these advancements, the integration of artificial intelligence and big data into manufacturing processes stands to revolutionize CNC machining. AI can streamline workflows, optimize resource allocation, and predict maintenance needs, thereby reducing downtime. As companies continue to adopt smart manufacturing techniques, the synergy between AI and CNC technologies will foster a new era of adaptability and responsiveness in production environments.

**Tips:**

1. Consider investing in AI-powered CNC systems to enhance automation and reduce manual errors.

2. Stay informed about industry trends and advancements, as continuous learning can provide a competitive edge in adopting new technologies.

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska