Unlocking the Potential of CNC Turning for Precision Manufacturing Success

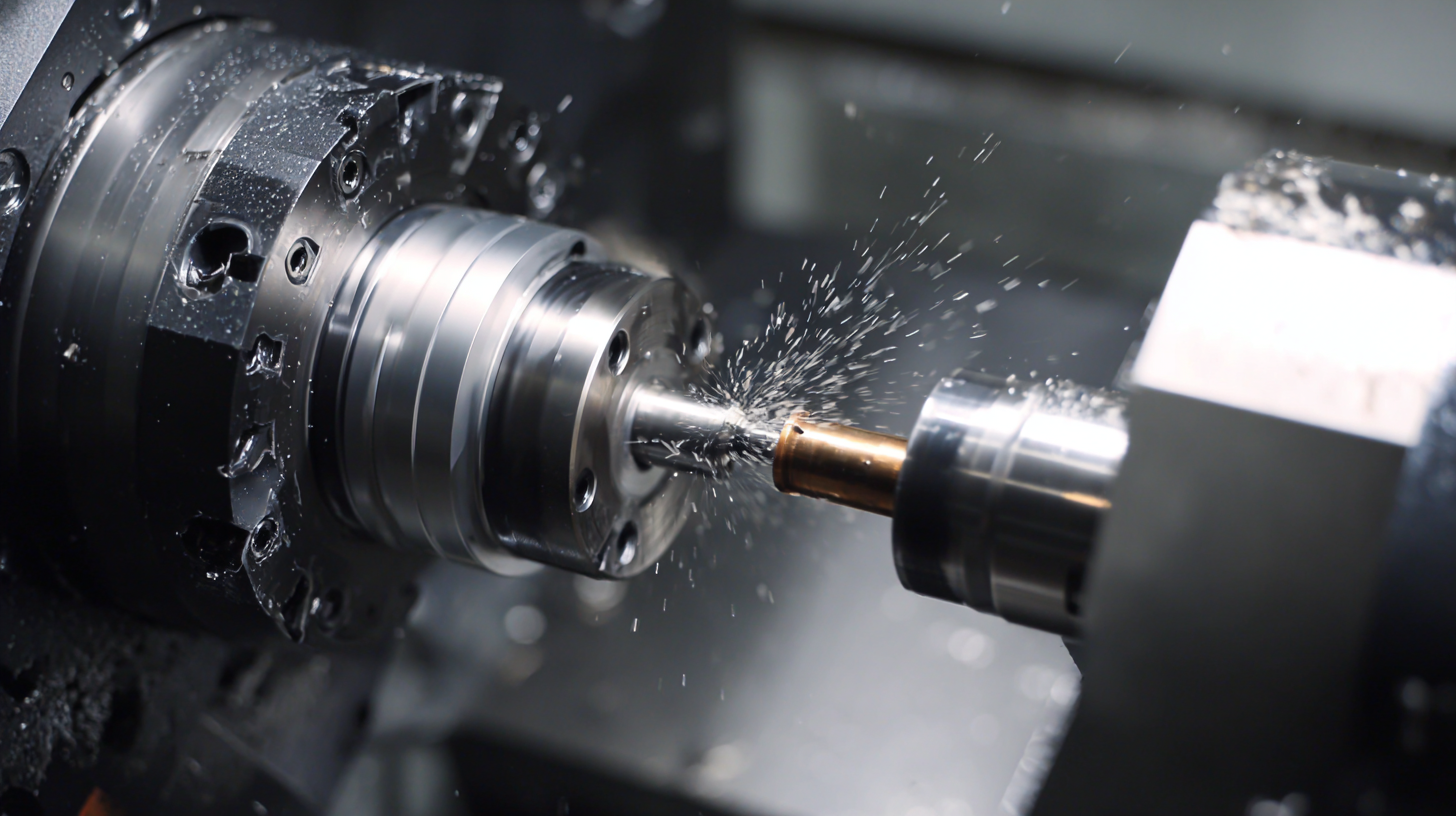

In the realm of precision manufacturing, **CNC turning** has emerged as a pivotal technology driving efficiency and accuracy. This advanced machining process utilizes computer numerical control to guide lathes and other tools, allowing manufacturers to create complex components with remarkable precision. As industry demands for high-quality and customized parts continue to escalate, understanding the intricacies of CNC turning becomes essential for success. This process not only enhances productivity but also reduces waste, thus leading to cost-effective manufacturing solutions. By unlocking the potential of CNC turning, businesses can achieve a competitive edge in their respective markets, making it imperative for them to stay abreast of the latest advancements and techniques in this field.

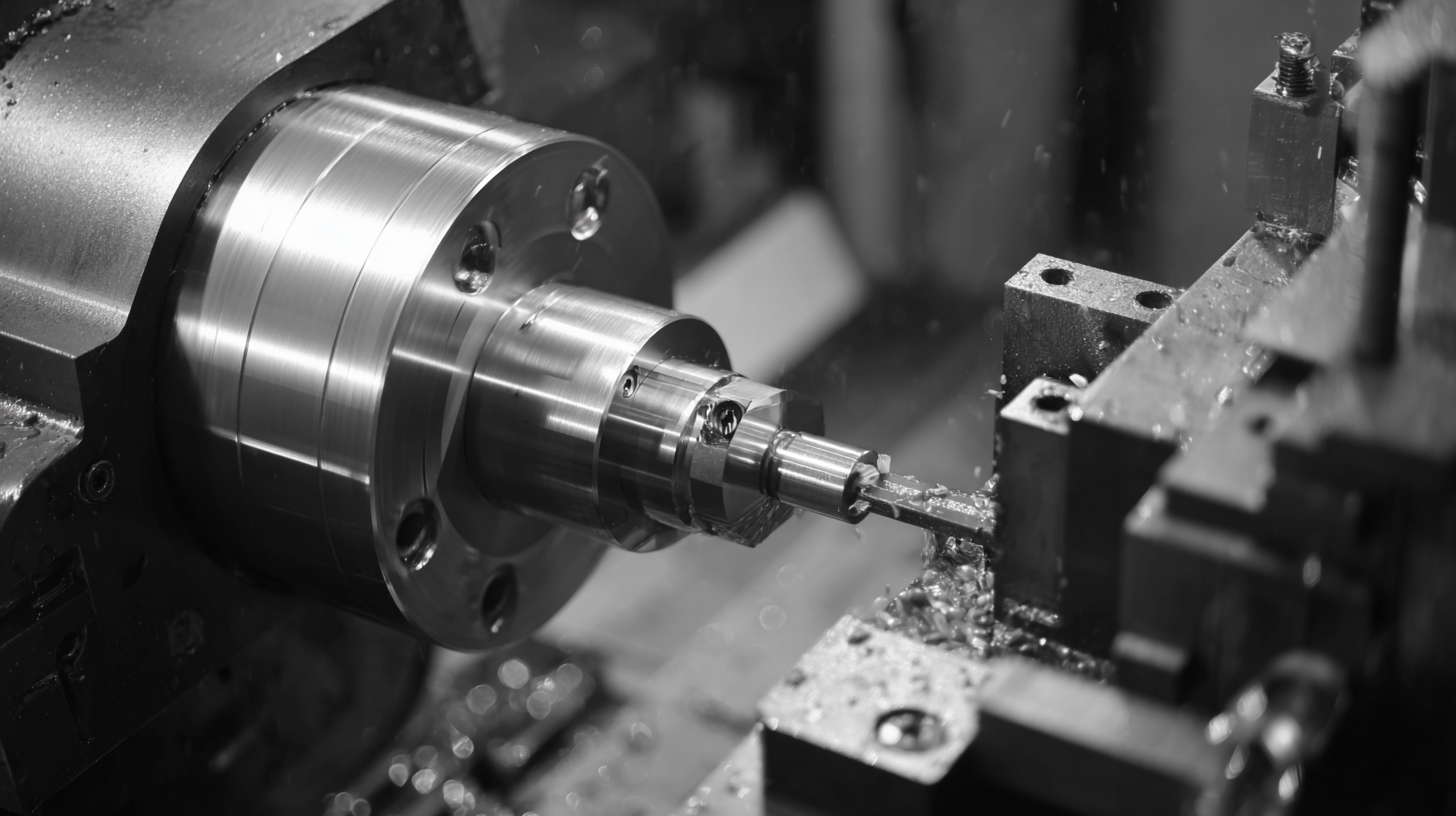

Understanding CNC Turning and Its Mechanisms

CNC turning is a pivotal process in precision manufacturing, allowing for the intricate shaping of materials with high accuracy. Understanding the mechanisms behind CNC turning helps in optimizing production efficiency, particularly when working with advanced materials like titanium matrix composites (TMCs). TMCs offer improved performance features compared to traditional titanium alloys, yet they present significant challenges in machining due to their unique properties. Recent investigations into tool wear during high-speed turning of TMCs have highlighted the importance of selecting the right cutting tools to enhance longevity and maintain precision.

Tips for CNC Turning Success:

1. Prioritize Tool Selection: Choose cutting tools that can withstand the unique abrasiveness of TMCs to minimize wear and ensure consistent quality.

2. Optimize Speed and Feed Rates: Adjusting the speed and feed rates to match the material's characteristics can lead to better surface finishes and reduced machining times.

3. Regular Monitoring: Implement in-situ monitoring of tool performance to promptly identify wear patterns and adjust processes accordingly.

Historically, tools like the precision lathe have been crucial for tasks requiring extreme detail, such as the creation of the Antikythera Mechanism. As CNC turning technology evolves, the integration of data-driven insights will further unlock its potential, making it an indispensable part of modern manufacturing processes. By mastering the mechanisms of CNC turning, manufacturers can achieve unprecedented levels of precision and efficiency.

Key Advantages of CNC Turning in Precision Manufacturing

CNC turning has emerged as a cornerstone of precision manufacturing, offering several key advantages that enhance productivity and efficiency. According to a recent industry report, the CNC turning market is expected to grow at a CAGR of 6% through the next five years, indicating a robust demand for this advanced manufacturing technique. One of the primary benefits of CNC turning is its ability to produce highly complex geometries with exceptional accuracy, often reaching tolerances of ±0.01 mm. This capability is especially critical in sectors such as aerospace and medical device manufacturing, where precision is paramount for safety and performance.

Moreover, the integration of digital technologies in CNC turning has further revolutionized manufacturing processes. With the implementation of smart automation and real-time monitoring systems, manufacturers can achieve significant reductions in cycle times—up to 30% in some cases—while minimizing material waste. A study by the Manufacturing Innovation Institute highlights that companies adopting CNC turning technologies have reported up to a 50% increase in operational efficiency. These advancements not only streamline production but also enhance the competitiveness of manufacturers in an increasingly demanding marketplace.

Unlocking the Potential of CNC Turning for Precision Manufacturing Success

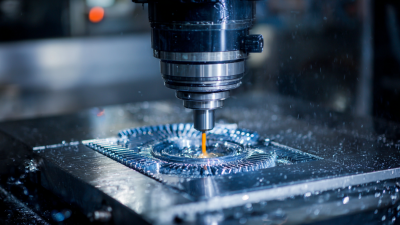

Applications of CNC Turning Across Various Industries

CNC turning is a pivotal process in precision manufacturing, widely utilized across various industries for its ability to create highly complex and accurate components. In aerospace, CNC turning plays a critical role in manufacturing components such as turbine blades and structural parts that require exceptional precision and strength. Similarly, in the automotive industry, it is essential for producing intricate engine components, transmission parts, and even custom fittings that demand accuracy and consistency.

Tips: When implementing CNC turning in your manufacturing process, ensure that you regularly maintain your machines to avoid costly downtimes. Additionally, invest in training for your operators to enhance their skills in programming and machine setup, as this can significantly elevate the quality and efficiency of your production.

In medical manufacturing, CNC turning is crucial for creating precise instruments and implants, where tolerances can directly impact patient safety. The versatility of this technology also extends to the electronics sector, where it is used to produce components like housings and connectors, which require precise dimensions to ensure interoperability with other devices.

Tips: Embrace advanced software for simulation and modeling in CNC turning to optimize your designs before actual production, which can help in identifying potential issues early in the process, thus saving time and resources.

Unlocking the Potential of CNC Turning for Precision Manufacturing Success - Applications of CNC Turning Across Various Industries

| Industry | CNC Turning Application | Materials Used | Benefits |

|---|---|---|---|

| Aerospace | Precision engine components | Titanium, Aluminum | High strength-to-weight ratio, precision |

| Automotive | Drive shafts, wheel hubs | Steel, Machined plastics | Durability, cost-effectiveness |

| Medical | Surgical instruments, implants | Stainless steel, Titanium | Biocompatibility, precision machining |

| Electronics | Connector housings, enclosures | Aluminum, Brass | Lightweight, good conductivity |

| Marine | Propeller shafts, fittings | Bronze, Stainless steel | Corrosion resistance, strength |

Challenges in CNC Turning and How to Overcome Them

CNC turning is essential for precision manufacturing, yet it presents specific challenges that need to be addressed to leverage its full potential. One major concern is worker safety, especially when handling heavy components, such as those weighing up to 45kg. According to the U.S. Occupational Safety and Health Administration (OSHA), workplace injuries can be significantly reduced when appropriate safety measures are implemented, including training and ergonomic tools. By prioritizing safety protocols and employing flexible manufacturing techniques, businesses can enhance production efficiency while ensuring a secure working environment.

Furthermore, advancements in technology, such as 3D printing, are being explored to tackle manufacturing challenges associated with traditional methods like CNC turning. Researchers at Tunghai University have conducted comparative studies on 3D printed headlight lenses versus CNC-machined options. Their findings suggest that 3D printing can overcome common constraints of conventional machining, such as complex geometries and material limitations. According to a report by Wohlers Associates, the additive manufacturing industry is projected to grow to over $21 billion by 2024, highlighting the potential of innovative technologies in enhancing manufacturing processes. By integrating such technologies with CNC turning, manufacturers can not only overcome existing challenges but also unlock new possibilities for precision and efficiency.

Future Trends in CNC Turning Technology for Competitive Advantage

The landscape of CNC turning technology is rapidly evolving, driven by advancements in digital manufacturing and precision engineering. As industries increasingly adopt these innovations, the CNC machine market is projected to experience significant growth, with estimates suggesting it could reach billions in value by the mid-2030s. This trend highlights the importance of enhancing productivity and efficiency, not only to meet rising demand but also to maintain a competitive edge in the global marketplace.

Emerging technologies, such as AI integration and improved metrology practices, are expected to further propel CNC turning capabilities. AI agents are transforming customer experiences, and their principles are being mirrored in manufacturing environments where predictive maintenance and smart automation are becoming the norms. The fusion of these technologies is paving the way for unprecedented levels of precision and customer satisfaction, ensuring that businesses can deliver high-quality products while optimizing their operational efficiency. As these trends continue to unfold, companies that stay ahead of the curve will reap the benefits of a technologically advanced production landscape.

Related Posts

-

Unlocking the Power of CNC Turning Tips for Global Buyers in the Digital Era

-

Exploring Unique Features and Applications of Best CNC Manufacturing Solutions

-

Shaping the Future of CNC Machines at the 138th Canton Fair in 2025

-

Unmatched Excellence in Best CNC Metal from Leading Chinese Manufacturers

-

The Future of Advanced CNC Machine Technologies in Global Manufacturing

-

Discovering the Advantages of the Best Smart CNC Technology for Modern Manufacturing

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska