Unlocking Global Markets: The Role of Import-Export Certifications for the Best Small CNC Machines in Metal Fabrication

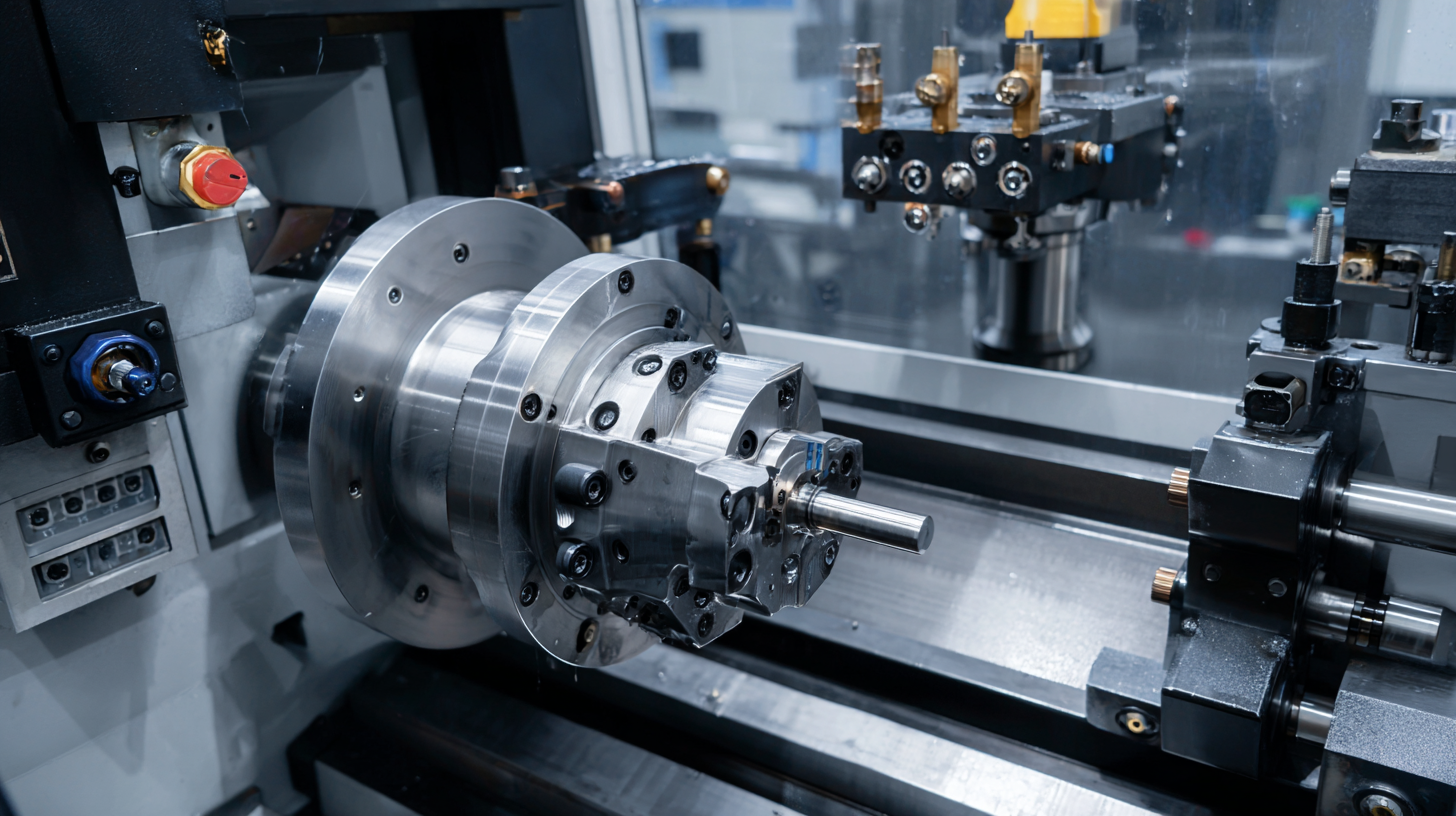

In today’s fast-paced manufacturing landscape, the significance of small CNC machines for metal fabrication cannot be overstated. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach USD 100 billion by 2025, underscoring the escalating demand for precision engineering and efficient production processes. Small CNC machines play a pivotal role in this growth, offering versatility and cost-effectiveness for small to medium enterprises. However, to fully capitalize on global opportunities, companies must navigate the intricacies of import-export certifications. These certifications not only ensure compliance with international standards but also enhance competitive advantage in foreign markets. By unlocking potential through proper certification, businesses can elevate their operations and tap into new revenue streams in an increasingly interconnected global economy.

The Crucial Role of Import-Export Certifications in CNC Machine Quality Assurance

In the rapidly evolving landscape of global trade, import-export certifications have become a critical marker of quality assurance, particularly in the realm of CNC machinery used in metal fabrication. These certifications not only serve as a guarantee of compliance with international standards but also instill confidence in buyers regarding the performance and longevity of small CNC machines. They ensure that the machinery produced meets the stringent quality benchmarks required for precision parts, which are essential in industries like automotive and aerospace.

Recent developments in precision machining highlight the importance of such certifications. For instance, companies involved in the manufacturing of bespoke components utilize advanced machines that are certified, ensuring that products like mold tools for carbon fiber and optimized heatsinks achieve a flawless surface finish and meet specific performance criteria. As Vietnam looks to enhance its export capabilities in 2024, embracing a culture of quality assurance through import-export certifications will undoubtedly bolster its position in the competitive market, attracting more global buyers seeking reliable CNC solutions.

Emerging Trends in 2025: Technologies Shaping Metal Fabrication and CNC Machinery

As we look ahead to 2025, the metal fabrication industry is poised for significant transformation, driven by emerging technologies and evolving market dynamics. With the global sheet metal processing equipment market projected to surge from $35.51 billion in 2025 to $61.78 billion by 2032, manufacturers are increasingly investing in advanced machinery. Innovations in machine tools and automation are not only enhancing productivity but also optimizing precision in metal fabrication processes. This shift highlights the crucial role that import-export certifications play, enabling manufacturers to access global markets while adhering to international standards.

In the bending machine sector, the market is expected to expand from USD 9.5 billion in 2024, fueled by rising demand across various industries. The introduction of smart machinery, powered by AI and IoT, enables real-time monitoring and data-driven decision-making, leading to greater efficiency and reduced downtime. As manufacturers leverage these technologies, they will be better equipped to meet the challenges of a competitive landscape, ensuring their offerings meet the evolving needs of customers globally.

Understanding Global Market Access: The Importance of Compliance in CNC Exports

Navigating global markets requires an understanding of compliance regulations, particularly in the CNC (Computer Numerical Control) industry. Exporting CNC machines, particularly small ones suitable for metal fabrication, necessitates a robust set of import-export certifications. These certifications not only facilitate access to new markets but also ensure adherence to international safety and quality standards, which is critical in the competitive landscape of manufacturing. Data from industry reports indicate that over 70% of manufacturers view compliance as a key determinant in their ability to export effectively.

In light of evolving global trade dynamics, Vietnam stands poised to capitalize on emerging opportunities in the export sector. The country's focus on enhancing its MSME (Micro, Small, and Medium Enterprises) export capabilities through e-commerce hubs offers a significant avenue for small CNC machine manufacturers to expand their reach. With Vietnam projected to see substantial export growth in 2024, investing in compliance certifications for CNC machines will be paramount for businesses looking to thrive in international markets.

**Tip:** Ensure that your CNC machines meet international certifications like ISO and CE to enhance marketability and compliance.

**Tip:** Engage in ongoing training for your staff on export regulations to stay updated with the latest compliance requirements, safeguarding your business from potential penalties.

Unlocking Global Markets: The Role of Import-Export Certifications for the Best Small CNC Machines in Metal Fabrication

| Certification Type | Importance | Applicable Markets | Compliance Requirements | Average Cost ($) |

|---|---|---|---|---|

| ISO 9001 | Quality Management Systems | Global | Documentation, Internal Audits | 2,500 |

| CE Marking | Conformity with EU Standards | European Union | Technical Documentation, Testing | 1,800 |

| UL Certification | Safety and Performance | North America | Testing, Documentation | 3,000 |

| RoHS Compliance | Restriction of Hazardous Substances | Global, especially EU | Materials Testing, Documentation | 1,200 |

| FCC Certification | Federal Communication Compliance | United States | Testing for Emissions | 2,000 |

Statistical Insights: Market Growth Projections for Small CNC Machines by 2025

The demand for small CNC machines in metal fabrication is projected to witness significant growth, aligning with broader trends in the machine tools market. As of 2024, the global machine tools market is valued at approximately USD 97.1 billion and is anticipated to reach an impressive USD 196 billion by 2034, reflecting a robust compound annual growth rate (CAGR) of 7.5%. This surge in demand is partly fueled by the increasing adoption of automation and advanced manufacturing technologies across various sectors, including aerospace and manufacturing.

Furthermore, projections for the desktop CNC machines segment indicate a favorable market trajectory. By 2033, the global desktop CNC machines market is expected to expand considerably, supported by the versatility and efficiency these machines offer in various applications. With rising operational efficiency and the growing trend toward personalization and small-batch production, small CNC machines are set to become indispensable tools in modern metal fabrication. As businesses aim to unlock global markets, understanding the critical role of import-export certifications will be essential for leveraging these machines' full potential and maximizing growth opportunities through 2025 and beyond.

The Competitive Edge: How Certifications Enhance the Value of CNC Machines in Global Trade

In today's fiercely competitive global market, certifications play a pivotal role in enhancing the value of CNC machines, particularly in the metal fabrication sector. For small enterprises looking to expand their reach, having recognized import-export certifications can be a game changer. These endorsements signify compliance with international standards, ensuring that products are of the highest quality and safety. As a result, buyers across various regions can trust that the CNC machines they purchase meet stringent regulatory requirements, giving sellers a significant competitive edge.

Moreover, certifications can greatly influence market perception and demand. When small CNC machine manufacturers have certifications that are respected worldwide, it not only boosts their credibility but also opens up new avenues for partnerships and collaborations. Global trade often hinges on the ability to meet local regulations and industry standards, and certified products are more likely to gain acceptance in diverse markets. Therefore, investing in the right certifications not only enhances the perceived value of CNC machines but also strengthens the overall brand positioning in the international arena.

English

English  Česká republika

Česká republika Deutsch

Deutsch Dutch

Dutch Polska

Polska